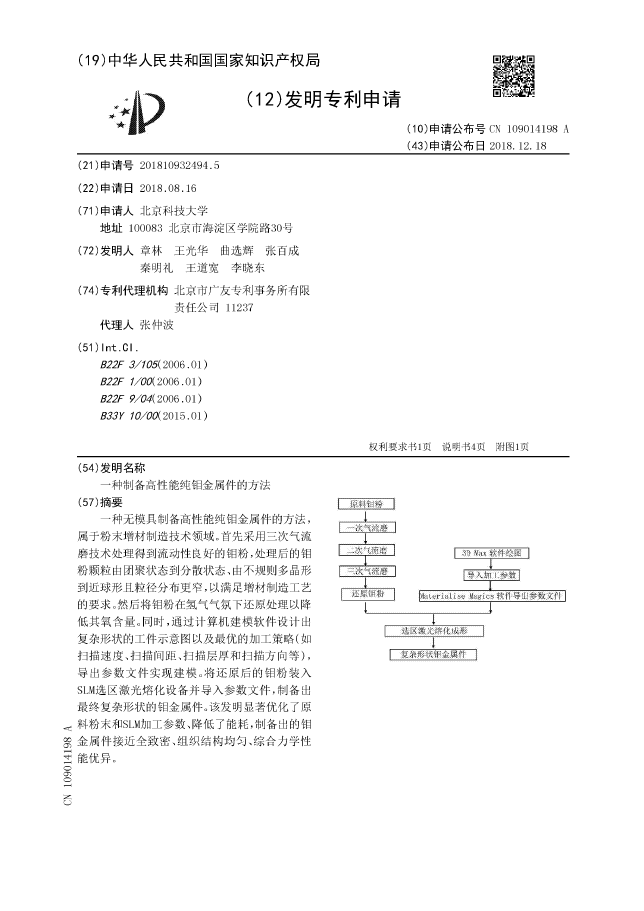

一种无模具制备高性能纯钼金属件的方法,属于粉末增材制造技术领域。首先采用三次气流磨技术处理得到流动性良好的钼粉,处理后的钼粉颗粒由团聚状态到分散状态、由不规则多晶形到近球形且粒径分布更窄,以满足增材制造工艺的要求。然后将钼粉在氢气气氛下还原处理以降低其氧含量。同时,通过计算机建模软件设计出复杂形状的工件示意图以及最优的加工策略(如扫描速度、扫描间距、扫描层厚和扫描方向等),导出参数文件实现建模。将还原后的钼粉装入SLM选区激光熔化设备并导入参数文件,制备出最终复杂形状的钼金属件。该发明显著优化了原料粉末和SLM加工参数、降低了能耗,制备出的钼金属件接近全致密、组织结构均匀、综合力学性能优异。

A method for preparing high-performance pure molybdenum metal parts without a mold belongs to the technical field of powder additive manufacturing. First, three jet milling technology is used to process molybdenum powder with good fluidity. The processed molybdenum powder particles change from agglomerated state to dispersed state, from irregular polycrystalline to nearly spherical, and have a narrower particle size distribution to meet the requirements of the additive manufacturing process. Require. Then the molybdenum powder is reduced in a hydrogen atmosphere to reduce its oxygen content. At the same time, a schematic diagram of a complex shape of the workpiece and the optimal processing strategy (such as scanning speed, scanning distance, scanning layer thickness and scanning direction, etc.) are designed through computer modeling software, and parameter files are exported to realize modeling. Load the reduced molybdenum powder into the SLM laser melting equipment and import the parameter file to prepare the final complex shape of the molybdenum metal part. The invention significantly optimizes raw material powder and SLM processing parameters, reduces energy consumption, and prepares molybdenum metal parts that are close to full density, uniform structure, and excellent comprehensive mechanical properties.