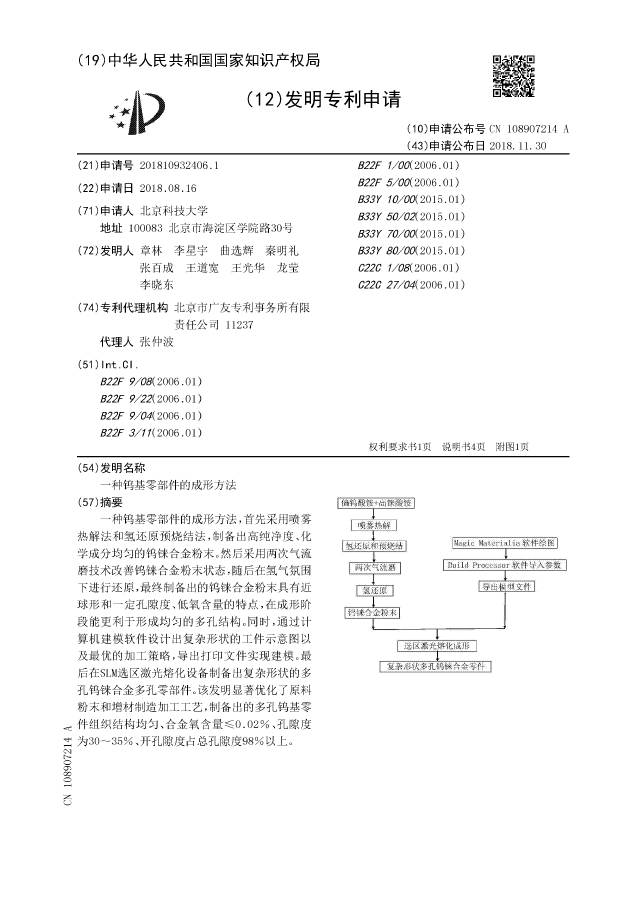

一种钨基零部件的成形方法,,属于粉末冶金技术领域。首先采用喷雾热解法和氢还原预烧结法,制备出高纯净度、化学成分均匀的钨铼合金粉末。然后采用两次气流磨技术改善钨铼合金粉末状态,随后在氢气氛围下进行还原,最终制备出的钨铼合金粉末具有近球形和一定孔隙度低氧含量的特点,在成形阶段能更利于形成均匀的多孔结构。同时,通过计算机建模软件设计出复杂形状的工件示意图以及最优的加工策略,导出打印文件实现建模。最后在SLM选区激光熔化设备制备出复杂形状的多孔钨铼合金多孔零部件。该发明显著优化了原料粉末和增材制造加工工艺,制备出的多孔钨基零件组织结构均匀、合金氧含量<0.02%、隙度为30~35%、开孔隙度占总孔隙度98%以上。

A forming method of tungsten-based parts belongs to the technical field of powder metallurgy. First, spray pyrolysis and hydrogen reduction pre-sintering are used to prepare tungsten rhenium alloy powder with high purity and uniform chemical composition. Then two jet milling techniques are used to improve the state of the tungsten-rhenium alloy powder, and then reduced in a hydrogen atmosphere. The final prepared tungsten-rhenium alloy powder has the characteristics of near spherical shape and a certain porosity and low oxygen content, which can be more conducive to formation in the forming stage Uniform porous structure. At the same time, the complicated shape of the workpiece schematic diagram and the optimal processing strategy are designed through the computer modeling software, and the printing file is exported to realize the modeling. Finally, a complex shape of porous tungsten-rhenium alloy porous parts was prepared by laser melting equipment in the SLM selected area. The invention significantly optimizes the raw material powder and additive manufacturing processing technology, and the prepared porous tungsten-based parts have a uniform structure, an alloy oxygen content of <0.02%, a gap of 30-35%, and an open porosity that accounts for more than 98% of the total porosity.