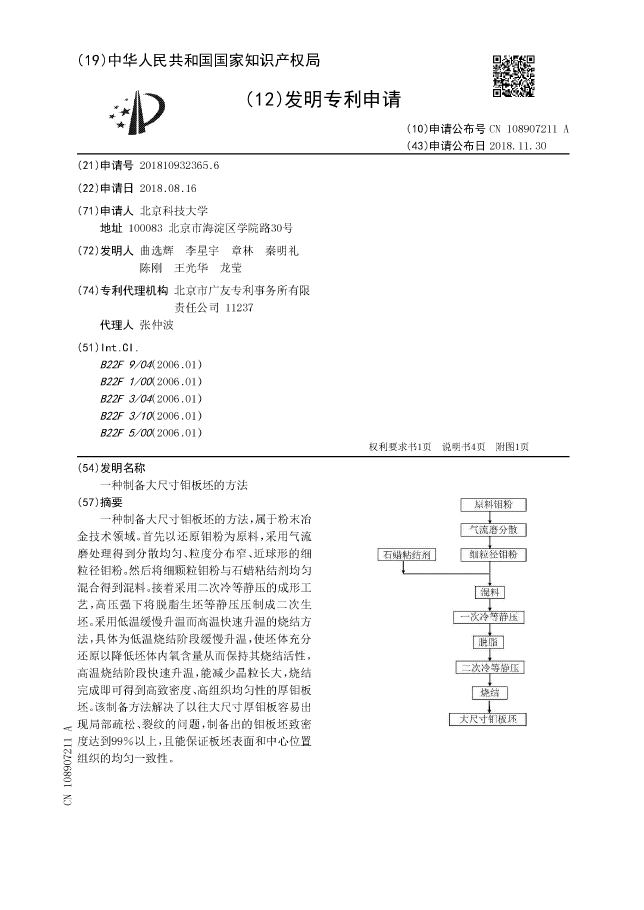

一种制备大尺寸钼板坯的方法,属于粉末冶金技术领域。首先以还原钼粉为原料,采用气流磨处理得到分散均匀、粒度分布窄、近球形的细粒径钼粉。然后将细颗粒钼粉与石蜡粘结剂均匀混合得到混料。接着采用二次冷等静压的成形工艺,高压强下将脱脂生坏等静压压制成二次生坏。采用低温缓慢升温而高温快速升温的烧结方法,具体为低温烧结阶段缓慢升温,使坯体充分还原以降低坯体内氧含量从而保持其烧结活性,高温烧结阶段快速升温,能减少晶粒长大,烧结完成即可得到高致密度、高组织均匀性的厚钼板坯。该制备方法解决了以往大尺寸厚钼板容易出现局部疏松、裂纹的问题,制备出的钼板坏致密度达到99%以上,且能保证板坏表面和中心位置组织的均匀一致性。

A method for preparing large-size molybdenum slabs belongs to the technical field of powder metallurgy. First, the reduced molybdenum powder is used as the raw material, and the jet mill is used to obtain the fine particle size molybdenum powder with uniform dispersion, narrow particle size distribution and nearly spherical shape. Then, the fine particle molybdenum powder and the paraffin wax binder are uniformly mixed to obtain a mixture. Then adopt the forming process of secondary cold isostatic pressing, degreasing and isostatic pressing under high pressure to make secondary growth. The sintering method adopts slow temperature rise at low temperature and rapid temperature rise at high temperature. Specifically, the temperature rises slowly in the low temperature sintering stage, so that the green body is fully reduced to reduce the oxygen content in the green body to maintain its sintering activity. The rapid temperature rise in the high temperature sintering stage can reduce the growth of crystal grains. After sintering, a thick molybdenum slab with high density and high structural uniformity can be obtained. The preparation method solves the problems that large-size thick molybdenum plates are prone to local looseness and cracks in the past, and the prepared molybdenum plates have a bad density of more than 99%, and can ensure the uniformity of the bad surface and the center position of the plate.