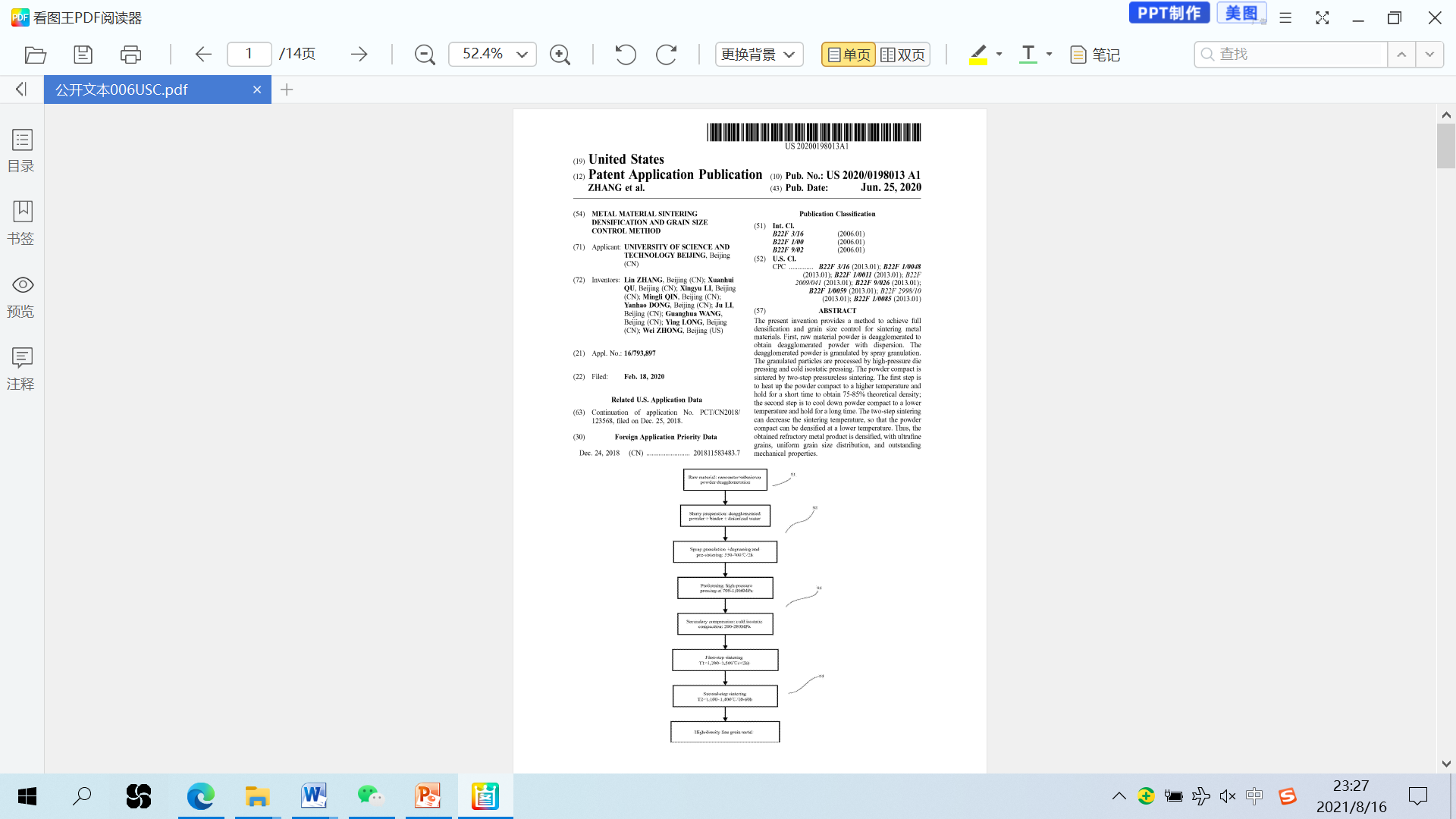

The invention belongs to the technical field of powder metallurgy, and in particular provides a method for sintering and densification of metal materials and crystal grain size control. The difference between the kinetics of grain boundary diffusion and grain boundary migration is used to suppress the growth of grains in the final stage. Using nano/submicron refractory metal powder as raw material, the raw material powder is pretreated first, and tungsten agglomerates are prepared by spray granulation, followed by pressing and cold isostatic pressing, and then a two-step sintering process is used to prepare high Dense, fine-grained, refractory metal. The first step of sintering is to quickly raise the temperature of the compact to a higher temperature T, and immediately lower the temperature to a lower temperature T2 after holding it for a short time. Because the method adopts pressureless sintering, it solves the accelerated growth of crystal grains in the final stage of the traditional sintering process of refractory metals, helps to improve the uniformity of crystal grains, and inhibits abnormal grain growth. It can prepare nearly fully dense tungsten products with a density greater than 99%, and can achieve near-final forming of refractory metal products. It is a low-cost method for preparing fine-grained refractory metals, and it is also suitable for other metal materials.

The invention belongs to the technical field of powder metallurgy, and in particular provides a method for sintering and densification of metal materials and crystal grain size control. The difference between the kinetics of grain boundary diffusion and grain boundary migration is used to suppress the growth of grains in the final stage. Using nano/submicron refractory metal powder as raw material, the raw material powder is pretreated first, and tungsten agglomerates are prepared by spray granulation, followed by pressing and cold isostatic pressing, and then a two-step sintering process is used to prepare high Dense, fine-grained, refractory metal. The first step of sintering is to quickly raise the temperature of the compact to a higher temperature T, and immediately lower the temperature to a lower temperature T2 after holding it for a short time. Because the method adopts pressureless sintering, it solves the accelerated growth of crystal grains in the final stage of the traditional sintering process of refractory metals, helps to improve the uniformity of crystal grains, and inhibits abnormal grain growth. It can prepare nearly fully dense tungsten products with a density greater than 99%, and can achieve near-final forming of refractory metal products. It is a low-cost method for preparing fine-grained refractory metals, and it is also suitable for other metal materials.