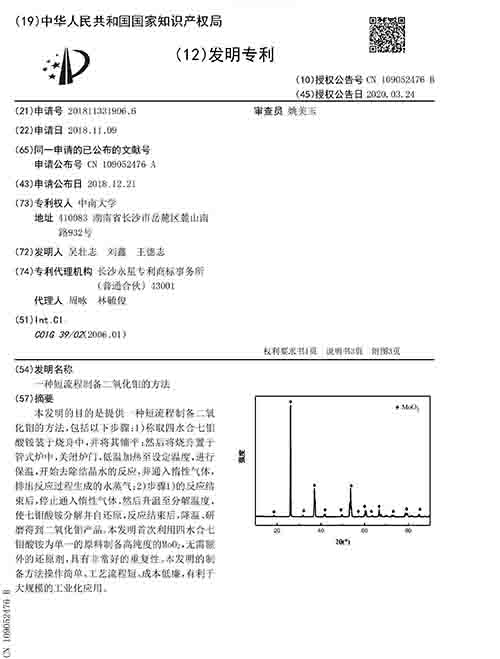

本发明的目的是提供一种短流程制备二氧 化钼的方法,包括以下步骤:1 )称取四水合七钼 酸铵装于烧舟中,并将其铺平;然后将烧舟置于管式炉中,关闭炉门,低温加热至设定温度,进行保温,开始去除结晶水的反应,并通入惰性气体, 排出反应过程生成的水蒸气;2)步骤1)的反应结 束后,停止通入惰性气体,然后升温至分解温度,使七钼酸铵分解并自还原,反应结束后,降温、研磨得到二氧化钼产品。本发明首次利用四水合七 钼酸铵为单一的原料制备高纯度的MoO2,无需额外的还原剂,具有非常好的重复性。本发明的制备方法操作简单、工艺流程短、成本低廉,有利于大规模的工业化应用。

The object of the present invention is to provide a short process of preparing molybdenum dioxide, including 1) after the reaction of taking quadruhydrate ammonium seven molybdate in the firing boat and flatten the firing boat in a tube furnace, close the furnace door, heat to the set temperature, insulation, remove the reaction of crystalline water, pass into the inert gas, the discharge process; 2) stop the inert gas, then heat to the decomposition temperature, decomposition of ammonium seven molybdate, after the reaction, cooling, grinding to the molybdenum dioxide product. For the first time, tetrahydrated ammonium monium seven molybdate has prepared highly purified MoO2, as a single raw material without an additional reducing agent and has excellent reproducibility. The preparation method of the invention is simple operation, short process and low cost, conducive to large-scale industrial applications.