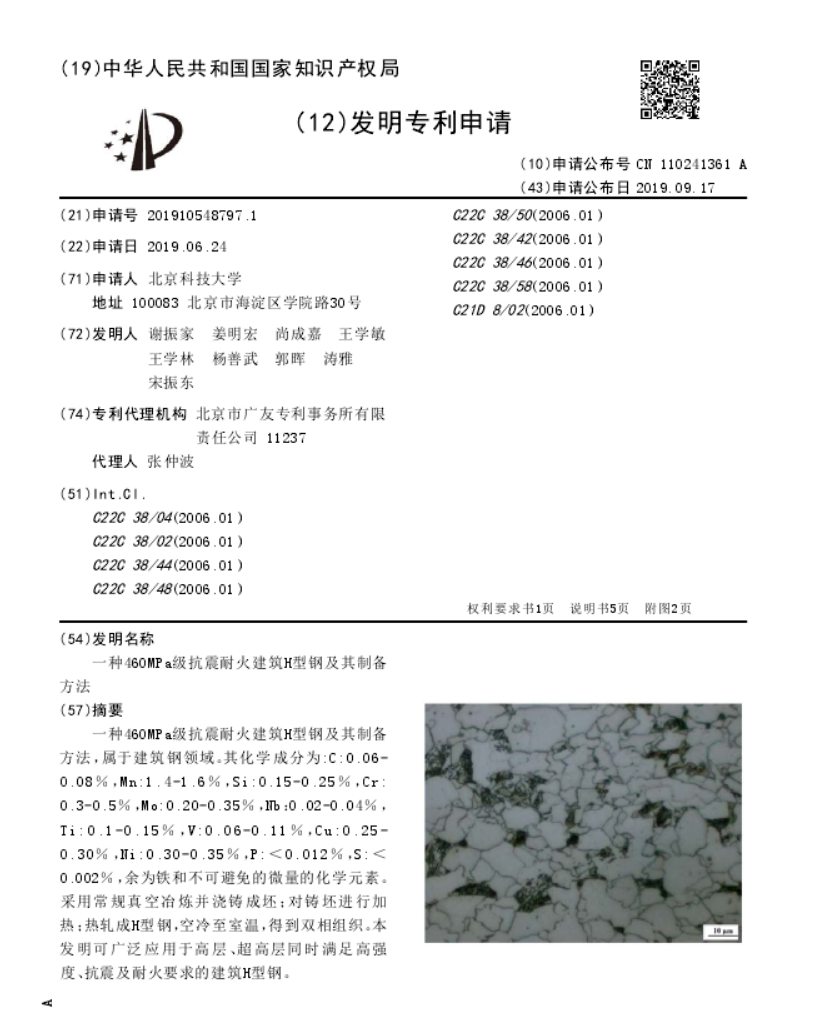

一种460MPa级抗震耐火建筑H型钢及其制备方法,属于建筑钢领域。其化学成分为:C:0.06-0.08%,Mn:1.4-1.6%,Si:0.15-0.25%,Cr:0.3-0.5%,Mo:0.20-0.35%,Nb:0.02-0.04%,Ti:0.1-0.15%,V:0.06-0.11%,Cu:0.25-0.30%,Ni:0.30-0.35%,P:<0.012%,S:<0.002%,余为铁和不可避免的微量的化学元素。采用常规真空冶炼并浇铸成坯;对铸坯进行加热;热轧成H型钢,空冷至室温,得到双相组织。本发明可广泛应用于高层、超高层同时满足高强度、抗震及耐火要求的建筑H型钢。

This invention is the production process of 460 MPa anti-seismic, fire-resistant H-beam steels. This material’s chemical composition is: C: 0.06~0.08%, Mn: 1.4~1.6%, Si: 0.15~0.25%, Cr: 0.3~0.5%, Mo: 0.20~0.35%, Nb: 0.02~0.04%, Ti: 0.1~0.15%, V: 0.06~0.11%, Cu: 0.25~0.30%, Ni: 0.30~ 0.35%,P: ≤ 0.012%, S: ≤ 0.002%, the remainder is iron and inevitable traces chemical element. The process is listed below: 1, using conventional vacuum smelting and casting into billets; 2, heating the cast billets; 3, hot rolling to H-beam steel and free cooling to room temperature to get dual-phase microstructure. The H-beam steel invented in this project is widely used in high-rise building, super-high-rise building and satisfy high strength, anti-seismic, fire resistance at the same time.