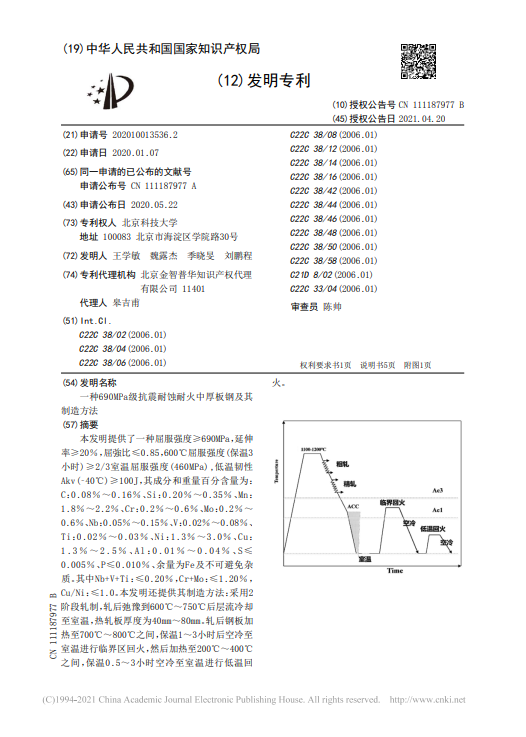

一种690MPa级抗震耐蚀耐火中厚板钢的制造方法,其特征在于,按合金成分配料,采用转炉炼钢,浇铸成连铸坯,再采用2阶段轧制,轧后弛豫到600℃~750℃后层流冷却至室温,热轧板厚度为40mm~80mm,然后进行两步回火,将热轧板重新加热至700℃~800℃之间,保温1~3小时后空冷至室温进行临界区回火,然后加热至200℃~400℃之间,保温0.5~3小时空冷至室温进行低温回火;所述2阶段轧制是先将连铸坯加热至1100℃~1200℃,保温2小时,然后进行轧制,第一阶段轧制终轧温度控制在950℃以上,第二阶段开轧温度控制在920℃~950℃,终轧温度为820℃~860℃,轧后弛豫到600℃~750℃后层流冷却至室温;热轧钢板厚度在40mm~80mm之间;中厚板钢化学成分按重量百分比计为:C:0.08%~0.16%、Si:0.20%~0.35%、Mn:1.8%~2.2%、Cr:0.2%~0.6%、Mo:0.2%~0.6%、Nb:0.05%~0.15%、V:0.02%~0.08%、Ti:0.02%~0.03%、Ni:1.3%~3.0%、Cu:1.3%~2.5%、Al:0.01%~0.04%、S≤0.005%、P≤0.010%、余量为Fe及不可避免杂质,其中Nb+V+Ti:≤0.20%,Cr+Mo:≤1.20%,Cu/Ni:≤1.0。

This invention is the production process of 690 MPa medium and heavy plate steels. The steel shows excellent mechanical properties: yield strength ≥ 690 MPa, yield ratio < 0.85, yield strength at 600℃ ≥ 2/3 yield strength at room temperature (460MPa), toughness at low temperature Akv(-40 ℃) ≥100J. This material’s chemical composition is: C: 0.08%~0.16%, Si: 0.20%~0.35%, Mn: 1.8%~2.2%, Cr: 0.2%~0.6%, Mo: 0.2%~0.6%, Nb: 0.05%~0.15%, V: 0.02%~0.03%, Ti: 0.02%~0.03%, Ni: 1.3%~3.0%, Cu: 1.3%~2.5%, Al: 0.01%~0.05%, S: ≤ 0.005%, P: ≤ 0.010%, the remainder is iron and inevitable traces chemical element. Especially, Nb + V+ Ti ≤ 0.20%, Cr+ Mo ≤ 1.20%, Cu/ Ni ≤ 1.0. Two-stage rolling is used in this process: free cooling to room temperature after rolling, and the thickness of hot rolling plate is 40mm~80mm. After rolling, the steel plate is heated to between 700°C and 800°C, kept for 1 to 3 hours and then air-cooled to room temperature for critical zone tempering, then heated to between 200°C and 400°C, and kept for 0.5 to 3 hours and air cooled to low temperature tempering at room temperature.