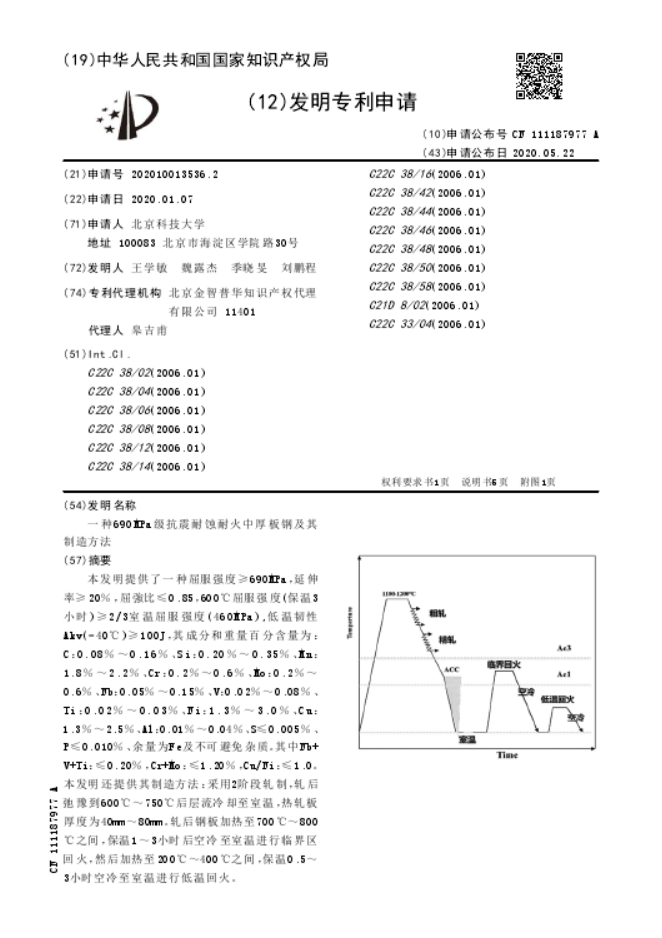

一种690MPa级抗震耐蚀耐火中板钢及其制造方法,其化学成分的重量百分比为:0.03%~0.10%C、0.20%~0.35%Si、Mn:1.50%~1.80%、Cr:0.20%~0.60%、Mo:0.20%~0.60%、Nb:0.02%~0.10%、V:0.02%~0.08%、Ti:0.02%~0.04%、Ni:1.00%~1.80%、Cu:1.00%~1.50%、Al:0.02%~0.04%、S≤0.005%、P≤0.010%、余量Fe及不可避免杂质,经一定条件的热轧及热处理工艺后,中板钢的室温屈服强度≥690MPa,延伸率≥18%,屈強比≤0.85,Akv(-40℃)/J≥200J。

This invention is the production process of 690 MPa anti-seismic, corrosion-resistant, fire-resistant medium plate steels. This material’s chemical composition is: C: 0.03%~0.10%, Si: 0.20%~0.35%, Mn: 1.50%~1.80%, Cr: 0.20%~0.60%, Mo: 0.20%~0.60%, Nb: 0.02%~0.10%, V: 0.02%~0.08%, Ti: 0.02%~0.04%, Ni: 1.00%~1.80%, Cu: 1.00%~1.50%, Al: 0.02%~0.04%, S: ≤ 0.005%, P: ≤ 0.010%, the remainder is iron and inevitable traces chemical element. After hot rolling and heat treatment, the steel invented in this project shows excellent mechanical properties: yield strength ≥ 690 MPa, elongation ≥ 18%, yield ratio ≤ 0.85, Akv(-40 ℃)/J ≥200J.