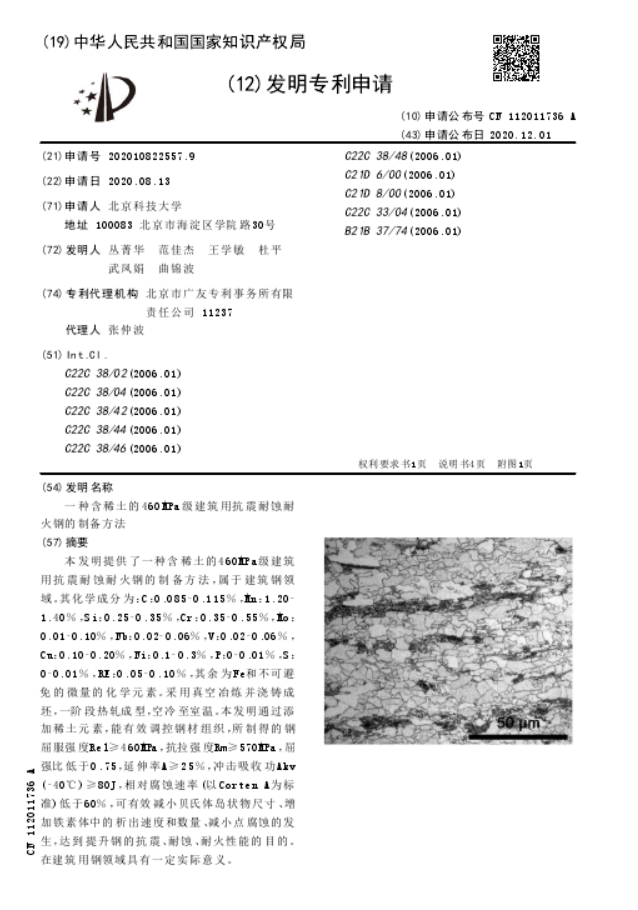

本发明提供了一种含稀土的460MPa级建筑用抗震耐蚀耐火钢的制备方法,属于建筑钢领域。其化学成分为:C:0.085-0.115%,Mn:1.20-1.40%,Si:0.25-0.35%,Cr:0.35-0.55%,Mo:0.01-0.10%,Nb:0.02-0.06%,V:0.02-0.06%,Cu:0.10-0.20%,Ni:0.1-0.3%,P:0-0.01%,S:0-0.01%,RE:0.05-0.10%,其余为Fe和不可避免的微量的化学元素。采用真空冶炼并浇铸成坯,一阶段热轧成型,空冷至室温。本发明通过添加稀土元素,能有效调控钢材组织,所制得的钢屈服强度Rel≥460MPa,抗拉强度Rm≥570MPa,屈强比低于0.75,延伸率A≥25%,冲击吸收功Akv(-40℃)≥80J,相对腐蚀速率(以Corten A为标准)低于60%,可有效减小贝氏体岛状物尺寸、增加铁素体中的析出速度和数量、减小点腐蚀的发生,达到提升钢的抗震、耐蚀、耐火性能的目的。在建筑用钢领域具有一定实际意义。

This invention is the production process of the 460 MPa building steel containing rare earth with anti-seismic, corrosion-resistance, fire-resistance. This material’s chemical composition is: C: 0.085~0.115%, Mn: 1.20~1.40%, Si: 0.25~0.35%, Cr: 0.35~0.55%, Mo: 0.01~0.10%, Ti: 0.05~0.12%, Nb: 0.02~0.06%, V: 0.02~0.06%, Cu: 0.10~0.20%, Ni: 0.1~0.3%, P: 0~0.01%, S: 0~0.01%, RE: 0.05~0.10%, the remainder is iron and inevitable traces chemical element. Using conventional vacuum smelting and casting into billets, then air cooling to room temperature. The invention can effectively control the structure of steel by adding rare earth elements. The steel shows excellent mechanical properties: yield strength ≥ 460 MPa, tensile strength > 570 MPa, yield ratio < 0.75, elongation ≥ 25%, impact absorption energy Akv( -40 ℃)≥80J, the relative corrosion rate (based on Corten A) is less than 60%. This steel can effectively reduce the size of bainite islands, increase the precipitation rate and quantity in ferrite, and reduce the occurrence of pitting corrosion to achieves the purpose of improving the anti-seismic, corrosion resistance and fire resistance.