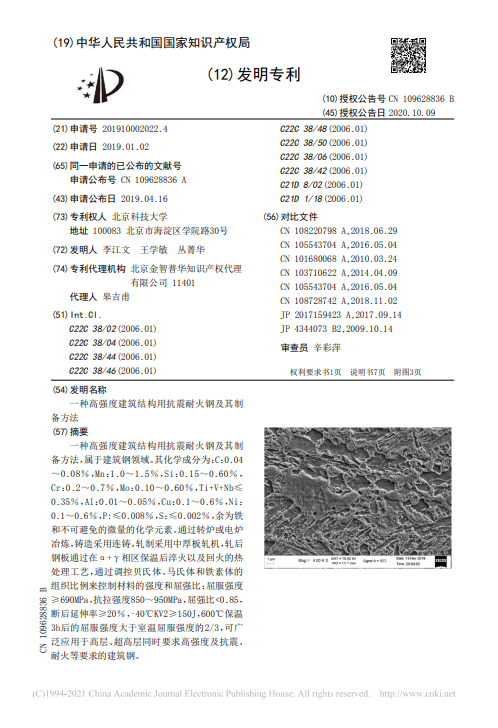

一种高强度建筑结构用抗震耐火钢及其制备方法,属于建筑钢领域。其化学成分为:C:0 .04 ~0 .08%,Mn:1 .0~1 .5%,Si:0 .15~0 .60%, Cr:0 .2~0 .7%,Mo:0 .10~0 .60%,Ti+V+Nb≤ 0 .35%,Al:0 .01~0 .05%,Cu:0 .1~0 .6%,Ni: 0 .1~0 .6%,P:≤0 .008%,S:≤0 .002%,余为铁 和不可避免的微量的化学元素。通过转炉或电炉冶炼,铸造采用连铸,轧制采用中厚板轧机,轧后钢板通过在α+γ相区保温后淬火以及回火的热处理工艺,通过调控贝氏体、马氏体和铁素体的 组织比例来控制材料的强度和屈强比;屈服强度 ≥690MPa,抗拉强度850~950MPa,屈强比﹤0 .85, 断后延伸率≥20%,‑40℃KV2≥150J,600℃保温 3h后的屈服强度大于室温屈服强度的2/3,可广 泛应用于高层、超高层同时要求高强度及抗震、 耐火等要求的建筑钢。

This invention is the production process of the high-strength building steel with anti-seismic, fire-resistant. This material’s chemical composition is: C: 0.04~0.08%, Mn: 1.0~1.5%, Si: 0.15~0.60%, Cr: 0.2~0.7%, Mo: 0.10~0.60%, Ti+ V+ Nb≤ 0.35%, Al: 0.01~0.05%, Cu: 0.1~0.6%, Ni: 0.1~0.6%, P: ≤ 0.008%, S: ≤ 0.002%, the remainder is iron and inevitable traces chemical element. It is smelted by converter or electric furnace, continuous casting and medium and heavy plate rolling mill is used. The rolled plate steel undergoes a quenching and tempering heat treatment process after heat preservation in the α+γ phase zone to control the microstructure ratio of bainite, martensite and ferrite, and control the strength and yield ratio of the steel. The steel shows excellent mechanical properties: yield strength ≥690 MPa, tensile strength 850~950 MPa, yield ratio < 0.85, elongation after fracture ≥ 20%, -40 ℃ KV2≥150J, yield strength at 600℃ ≥ 2/3 yield strength at room temperature. This steel is widely used in high-rise building, super-high-rise building and satisfy high strength, anti-seismic, fire resistance at the same time.