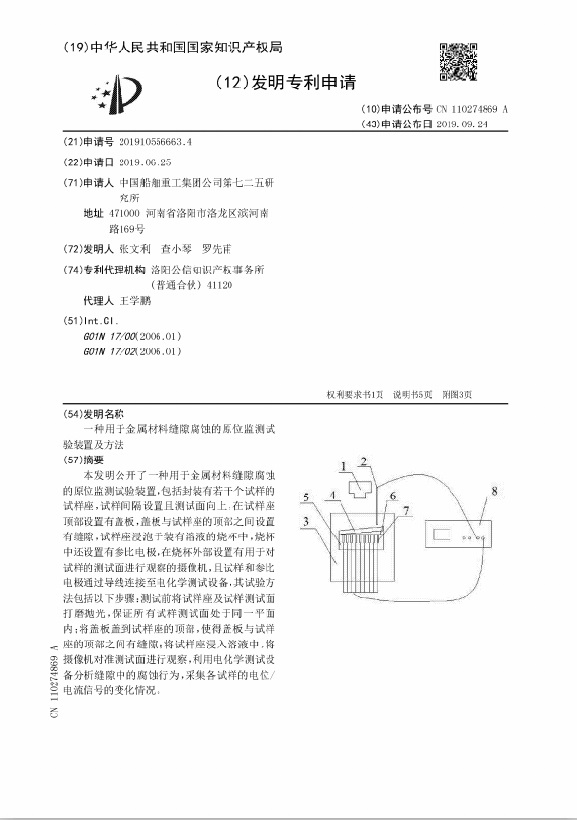

在装备生产制造过程中以及服役过程中不可避免的会在各种接头以及附着物的位置处形成缝隙,当这种装备处于腐蚀环境中时有发生缝隙腐蚀的危险,而且这种腐蚀形式有不易监测、危害性大的特点,严重威胁装备的安全和服役寿命。由于缝隙的存在形式多样、形状复杂,对金属的缝隙腐蚀行为进行研究有一定难度,发明这样一种可以原位观察缝隙腐蚀的试验方法有利于直观的观察腐蚀的产生及演变过程,并准确获取腐蚀出现的具体时间和位置,进而对金属材料的缝隙腐蚀行为进行深入的研究,为材料选择及改进提供数据支撑。这对于预防缝隙腐蚀产生以及缝隙腐蚀的修复有重要的科研和工程应用价值。

In the equipment manufacturing process and the service process, crevices will inevitably be formed at the positions of various joints and attachments. When this equipment is in a corrosive environment, there is a risk of crevice corrosion, and this type of corrosion is not easy. The characteristics of monitoring and harmfulness seriously threaten the safety and service life of equipment. Due to the various forms and complex shapes of crevices, it is difficult to study the crevice corrosion behavior of metals. Inventing such a test method that can observe crevice corrosion in situ is beneficial to visually observe the corrosion generation and evolution process, and accurately obtain The specific time and location of corrosion, and then in-depth research on the crevice corrosion behavior of metal materials, to provide data support for material selection and improvement. This has important scientific research and engineering application value for preventing crevice corrosion and repairing crevice corrosion.