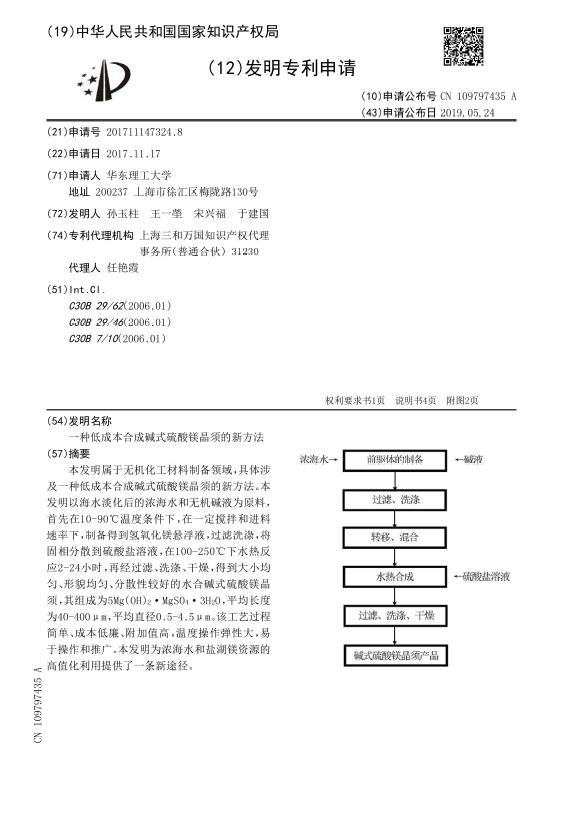

本发明属于无机化工材料制备领域,具体涉及一种低成本合成碱式硫酸镁晶须的新方法。本发明以海水淡化后的浓海水和无机碱液为原料,首先在10-90℃温度条件下,在一定搅拌和进料速率下,制备得到氢氧化镁悬浮液,过滤洗涤,将固相分散到硫酸盐溶液,在100-250℃下水热反应2-24小时,再经过滤、洗涤、干燥,得到大小均匀、形貌均匀、分散性较好的水合碱式硫酸镁晶须,其组成为5Mg(OH)2·MgSO4·3H2O,平均长度为40-400μm,平均直径0.5-4.5μm。该工艺过程简单、成本低廉、附加值高,温度操作弹性大,易于操作和推广。本发明为浓海水和盐湖镁资源的高值化利用提供了一条新途径。

The invention belongs to the field of preparation of inorganic chemical materials, and specifically relates to a new method for synthesizing basic magnesium sulfate whiskers at low cost. The present invention uses concentrated seawater and inorganic lye after seawater desalination as raw materials. Firstly, under the condition of temperature of 10-90°C, a certain stirring and feeding rate, the magnesium hydroxide suspension is prepared, filtered and washed, and the solid phase is dispersed. Then the solid phase is dispersed into the sulfate solution, and the hydrothermal reaction is conducted at 100-250°C for 2-24 hours. Then the solid phase is filtered, washed and dried, obtaining hydrated basic magnesium sulfate whiskers with uniform size and morphology and good dispersibility. The composition of solid product is 5Mg(OH)2·MgSO4·3H2O, the average length is 40-400μm, and the average diameter is 0.5-4.5μm. The process is simple, low in cost, high in added value, flexible in temperature operation, and easy to operate and popularize. The invention provides a new way for the high-value utilization of magnesium resources of concentrated seawater and salt lakes.