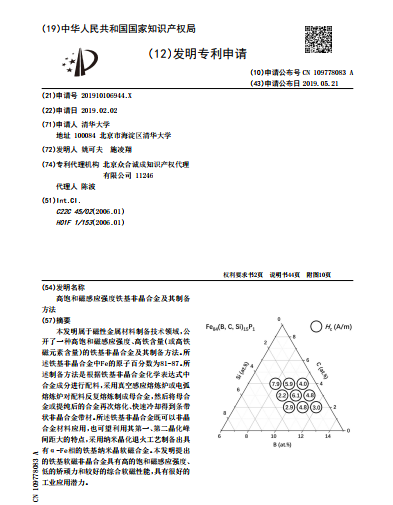

本发明属于磁性金属材料制备技术领域,公开了一种高饱和磁感应强度、高铁含量(或高铁磁元素含量)的铁基非晶合金及其制备方法。所述铁基非晶合金中Fe的原子百分数为81‑87。所述制备方法是根据铁基非晶合金化学表达式中合金成分进行配料,采用真空感应熔炼炉或电弧熔炼炉对配料反复熔炼制成母合金,然后将母合金或提纯后的合金再次熔化、快速冷却得到条带状非晶合金带材。所述铁基非晶合金既可以非晶合金材料应用,也可望利用其第一、第二晶化峰间距大的特点,采用纳米晶化退火工艺制备出具有α‑Fe相的铁基纳米晶软磁合金。本发明提出的铁基软磁非晶合金具有高的饱和磁感应强度、低的矫顽力和较好的综合软磁性能,具有很好的工业应用潜力。

The invention belongs to the technical field of magnetic metal material preparation, and discloses an iron-based amorphous alloy with high saturation magnetic induction intensity and high iron content (or high ferromagnetic element content) and a preparation method thereof. The atomic percentage of Fe in the iron-based amorphous alloy is 81-87. The preparation method is based on the alloy composition in the iron-based amorphous alloy chemical expression, the ingredients are repeatedly smelted into a master alloy using a vacuum induction melting furnace or an electric arc melting furnace, and then the master alloy or the purified alloy is melted again. Rapid cooling obtains a strip-shaped amorphous alloy strip. The iron-based amorphous alloy can be used as an amorphous alloy material, and it is also expected to take advantage of the large distance between the first and second crystallization peaks to prepare iron-based nanocrystalline soft magnetic alloy with α-Fe phase by using a nanocrystalline annealing process. The iron-based soft magnetic amorphous alloy proposed by the present invention has high saturation magnetic induction, low coercivity and better comprehensive soft magnetic properties, and has good industrial application potential.