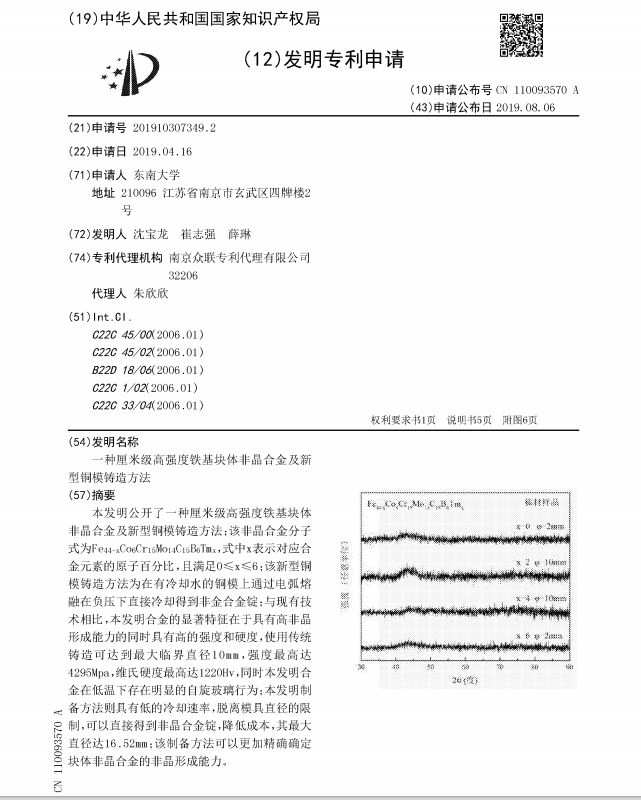

本发明公开了一种厘米级高强度铁基块体非晶合金及新型铜模铸造方法;该非晶合金分子式为Fe44‑xCo6Cr15Mo14C15B6Tmx,式中x表示对应合金元素的原子百分比,且满足0≤x≤6;该新型铜模铸造方法为在有冷却水的铜模上通过电弧熔融在负压下直接冷却得到非金合金锭;与现有技术相比,本发明合金的显著特征在于具有高非晶形成能力的同时具有高的强度和硬度,使用传统铸造可达到最大临界直径10mm,强度最高达4295Mpa,维氏硬度最高达1220Hv,同时本发明合金在低温下存在明显的自旋玻璃行为;本发明制备方法则具有低的冷却速率,脱离模具直径的限制,可以直接得到非晶合金锭,降低成本,其最大直径达16.52mm;该制备方法可以更加精确确定块体非晶合金的非晶形成能力。

The invention discloses a centimeter-level high-strength iron-based bulk amorphous alloy and a new copper mold casting method; the amorphous alloy molecular formula is Fe44-xCo6Cr15Mo14C15B6Tmx, where x represents the atomic percentage of the corresponding alloy element, and satisfies 0≤x ≤6; The new copper mold casting method is to obtain non-gold alloy ingots by arc melting on a copper mold with cooling water and direct cooling under negative pressure; compared with the prior art, the remarkable feature of the alloy of the present invention is that it has high non-gold alloy ingots. The crystal forming ability has high strength and hardness at the same time. The maximum critical diameter of 10mm can be reached by traditional casting, the strength is up to 4295Mpa, and the Vickers hardness is up to 1220Hv. At the same time, the alloy of the present invention has obvious spin glass behavior at low temperature; The inventive preparation method has a low cooling rate, breaks away from the limitation of the mold diameter, and can directly obtain amorphous alloy ingots, reducing costs, and its maximum diameter is 16.52mm; this preparation method can more accurately determine the amorphous formation of bulk amorphous alloys ability.