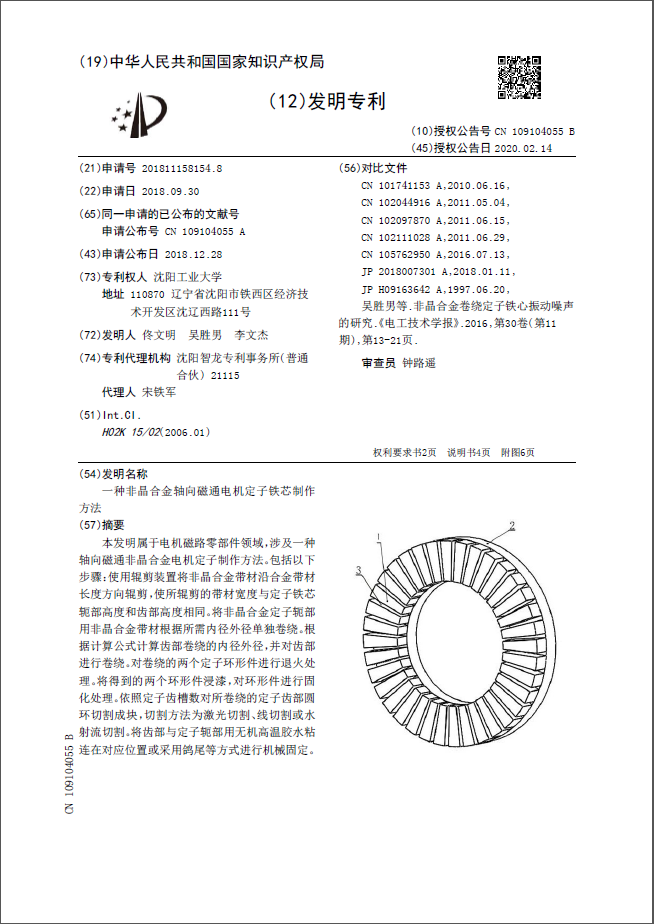

本发明属于电机磁路零部件领域,涉及一种轴向磁通非晶合金电机定子制作方法。包括以下步骤:使用辊剪装置将非晶合金带材沿合金带材长度方向辊剪,使所辊剪的带材宽度与定子铁芯轭部高度和齿部高度相同。将非晶合金定子轭部用非晶合金带材根据所需内径外径单独卷绕。根据计算公式计算齿部卷绕的内径外径,并对齿部进行卷绕。对卷绕的两个定子环形件进行退火处理。将得到的两个环形件浸漆,对环形件进行固化处理。依照定子齿槽数对所卷绕的定子齿部圆环切割成块,切割方法为激光切割、线切割或水射流切割。将齿部与定子轭部用无机高温胶水粘连在对应位置或采用鸽尾等方式进行机械固定。

The invention belongs to the field of motor magnetic circuit parts, and relates to a method for manufacturing an axial flux amorphous alloy motor stator. It includes the following steps: using a roll shear device to roll the amorphous alloy strip along the length of the alloy strip so that the width of the strip cut is the same as the height of the stator core yoke and the height of the teeth. The amorphous alloy strip for the yoke of the amorphous alloy stator is individually wound according to the required inner diameter and outer diameter. Calculate the inner diameter and outer diameter of the tooth winding according to the calculation formula, and wind the tooth. Anneal the two wound stator rings. The two ring parts obtained are dipped in paint, and the ring parts are cured. According to the number of stator tooth slots, the wound stator tooth ring is cut into pieces, and the cutting method is laser cutting, wire cutting or water jet cutting. The teeth and the stator yoke are glued to the corresponding positions with inorganic high-temperature glue or mechanically fixed by means of dovetail.