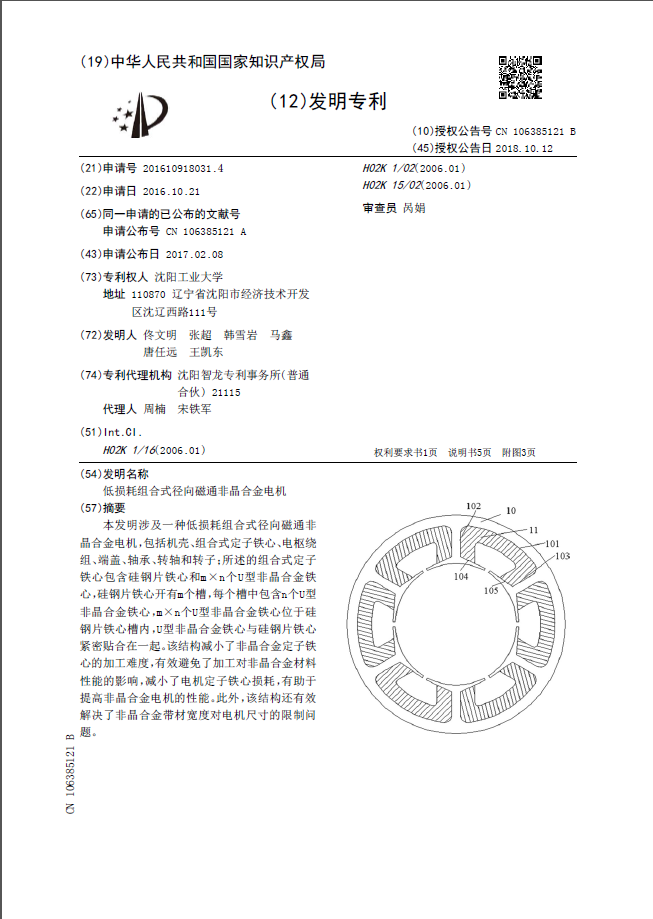

本发明涉及一种低损耗组合式径向磁通非晶合金电机,包括机壳、组合式定子铁心、电枢绕组、端盖、轴承、转轴和转子;所述的组合式定子铁心包含硅钢片铁心和m×n个U型非晶合金铁心,硅钢片铁心开有m个槽,每个槽中包含n个U型非晶合金铁心,m×n个U型非晶合金铁心位于硅钢片铁心槽内,U型非晶合金铁心与硅钢片铁心紧密贴合在一起。该结构减小了非晶合金定子铁心的加工难度,有效避免了加工对非晶合金材料性能的影响,减小了电机定子铁心损耗,有助于提高非晶合金电机的性能。此外,该结构还有效解决了非晶合金带材宽度对电机尺寸的限制问题。

The invention relates to a low-loss combined radial magnetic flux amorphous alloy motor, comprising a casing, a combined stator core, armature windings, end covers, bearings, a rotating shaft and a rotor; the combined stator core contains silicon steel sheets Iron core and m×n U-shaped amorphous alloy iron cores. The silicon steel sheet iron core has m slots, each slot contains n U-shaped amorphous alloy iron cores, and m×n U-shaped amorphous alloy iron cores are located in the silicon steel sheet iron core. In the groove, the U-shaped amorphous alloy core and the silicon steel sheet core are closely attached to each other. The structure reduces the difficulty of processing the amorphous alloy stator core, effectively avoids the effect of processing on the performance of the amorphous alloy material, reduces the motor stator core loss, and helps to improve the performance of the amorphous alloy motor. In addition, this structure also effectively solves the problem of the limitation of the width of the amorphous alloy strip on the size of the motor.