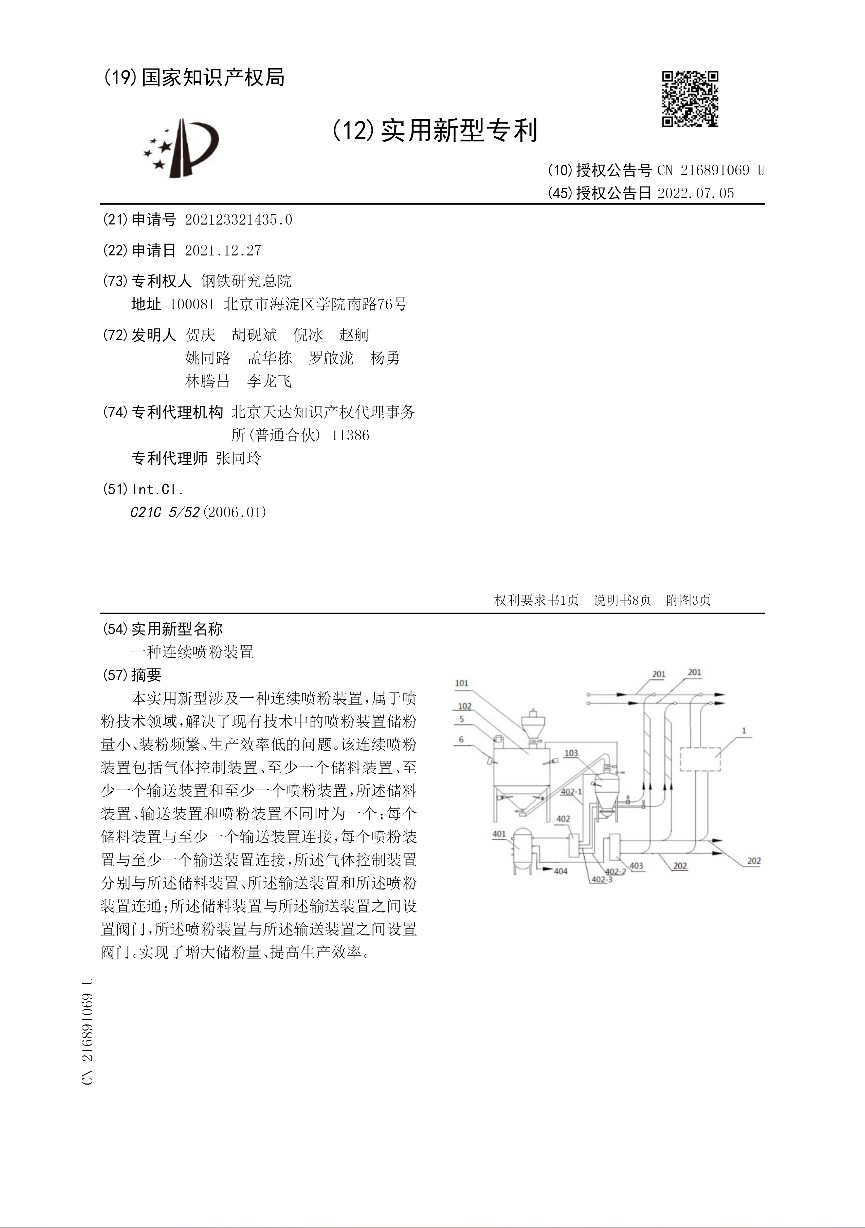

本实用新型涉及一种连续喷粉装置,属于喷粉技术领域,解决了现有技术中的喷粉装置储粉量小、装粉频繁、生产效率低的问题。该连续喷粉装置包括气体控制装置、至少一个储料装置、至少一个输送装置和至少一个喷粉装置,所述储料装置、输送装置和喷粉装置不同时为一个;每个储料装置与至少一个输送装置连接,每个喷粉装置与至少一个输送装置连接,所述气体控制装置分别与所述储料装置、所述输送装置和所述喷粉装置连通;所述储料装置与所述输送装置之间设置阀门,所述喷粉装置与所述输送装置之间设置阀门。实现了增大储粉量、提高生产效率。

The utility model relates to a continuous powder spraying device, belonging to the field of powder spraying technology, which solves the problems of small powder storage capacity, frequent powder loading, and low production efficiency in the existing technology of powder spraying devices. The continuous powder spraying device includes a gas control device, at least one material storage device, at least one conveying device, and at least one powder spraying device. The storage device, conveying device, and powder spraying device are not the same; Each material storage device is connected to at least one conveying device, each powder spraying device is connected to at least one conveying device, and the gas control device is respectively connected to the material storage device, the conveying device, and the powder spraying device; A valve is set between the storage device and the conveying device, and a valve is set between the powder spraying device and the conveying device. It has achieved an increase in powder storage and improved production efficiency.