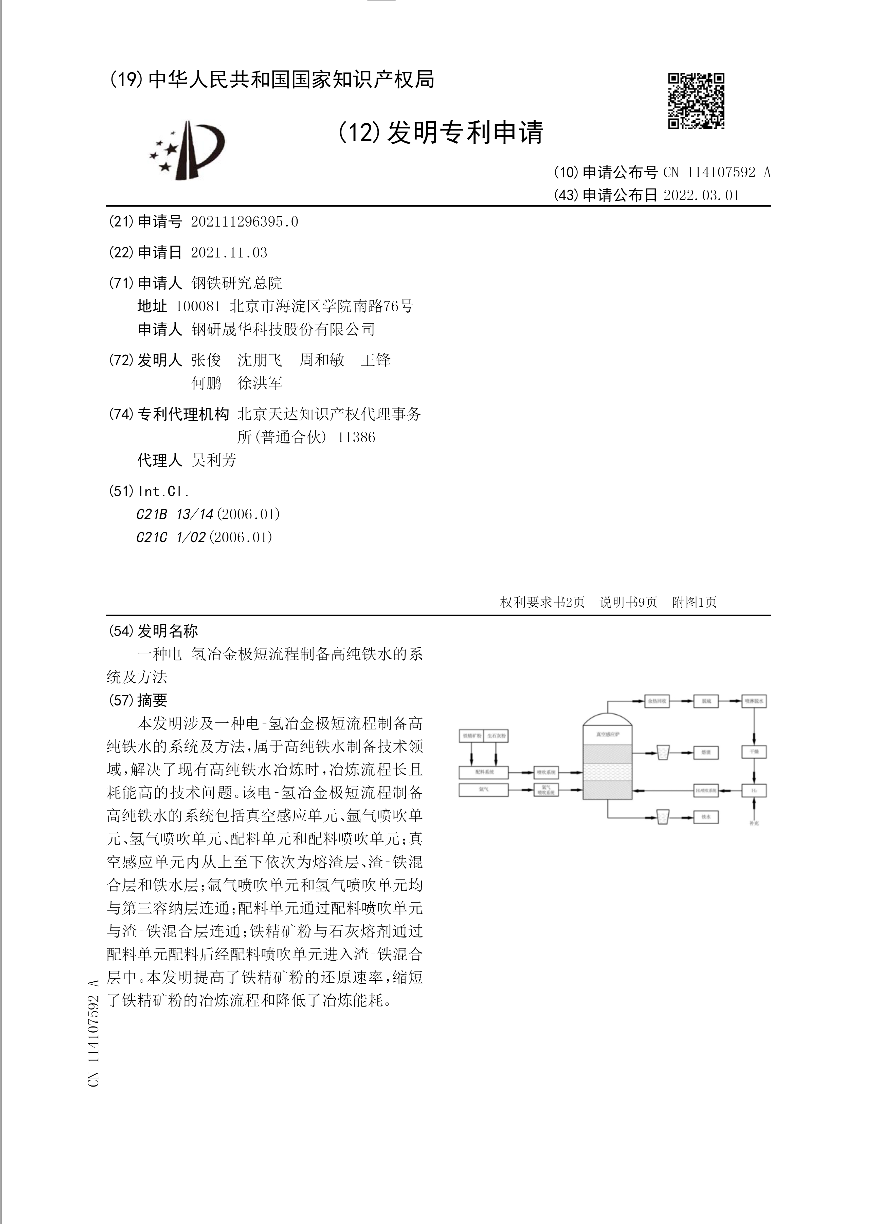

本发明涉及一种电‑氢冶金极短流程制备高纯铁水的系统及方法,属于高纯铁水制备技术领域,解决了现有高纯铁水冶炼时,冶炼流程长且耗能高的技术问题。该电‑氢冶金极短流程制备高纯铁水的系统包括真空感应单元、氩气喷吹单元、氢气喷吹单元、配料单元和配料喷吹单元;真空感应单元内从上至下依次为熔渣层、渣‑铁混合层和铁水层;氩气喷吹单元和氢气喷吹单元均与第三容纳层连通;配料单元通过配料喷吹单元与渣‑铁混合层连通;铁精矿粉与石灰熔剂通过配料单元配料后经配料喷吹单元进入渣‑铁混合层中。本发明提高了铁精矿粉的还原速率,缩短了铁精矿粉的冶炼流程和降低了冶炼能耗。

The present invention relates to a system and method for preparing high-purity molten iron through an extremely short process of electric hydrogen metallurgy, belonging to the field of high-purity molten iron preparation technology. It solves the technical problems of long smelting process and high energy consumption in the existing high-purity molten iron smelting. The system for preparing high-purity molten iron using the ultra-short process of hydrogen metallurgy includes a vacuum induction unit, an argon injection unit, a hydrogen injection unit, a batching unit, and a batching injection unit; The vacuum induction unit consists of a slag layer, a slag iron mixed layer, and an iron water layer from top to bottom; The argon injection unit and the hydrogen injection unit are both connected to the third containment layer; The batching unit is connected to the slag iron mixing layer through the batching spraying unit; Iron concentrate powder and lime flux are batched through the batching unit and then enter the slag iron mixing layer through the batching and blowing unit. The present invention improves the reduction rate of iron concentrate powder, shortens the smelting process of iron concentrate powder, and reduces smelting energy consumption.