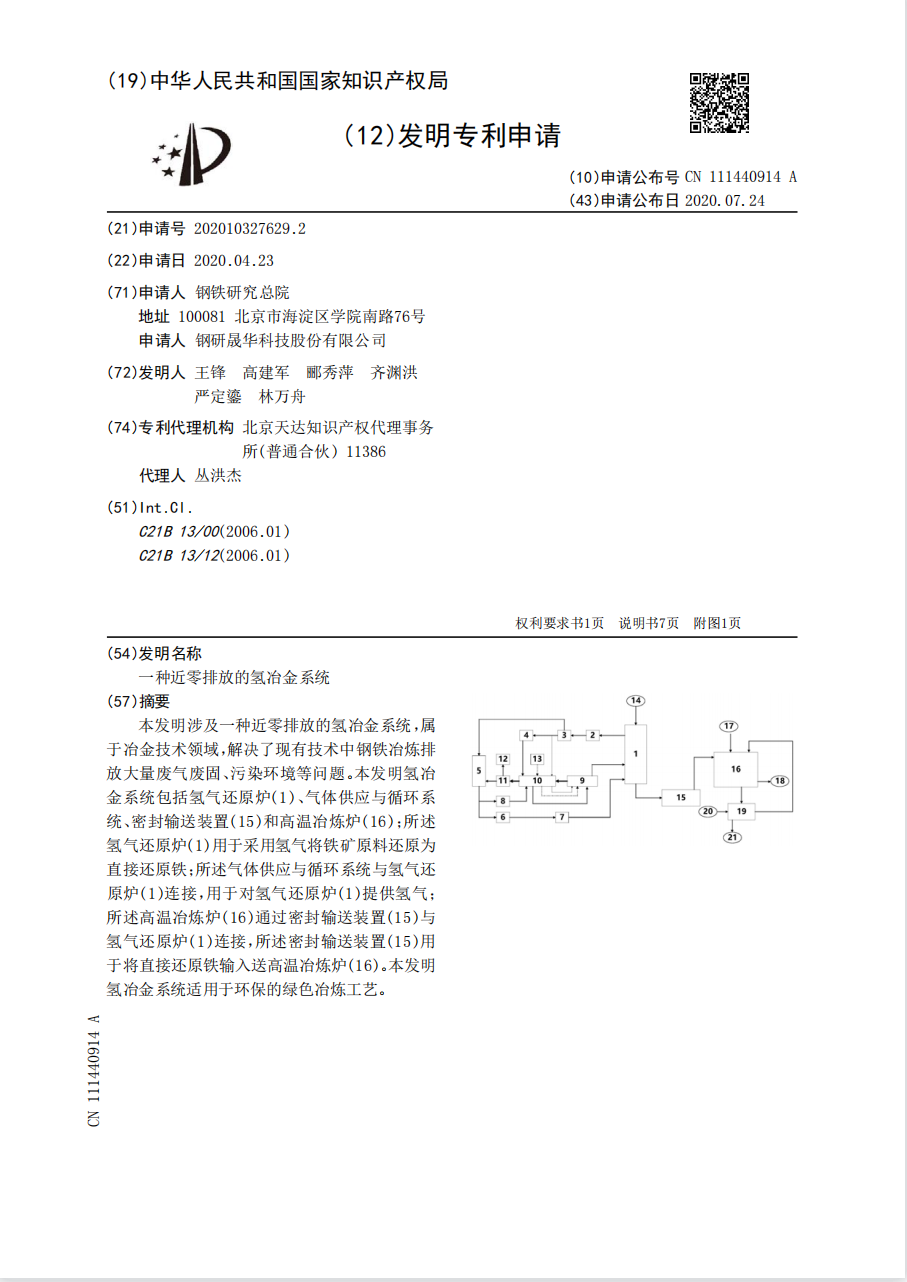

本发明涉及一种近零排放的氢冶金系统,属于冶金技术领域,解决了现有技术中钢铁冶炼排放大量废气废固、污染环境等问题。本发明氢冶金系统包括氢气还原炉(1)、气体供应与循环系统、密封输送装置(15)和高温冶炼炉(16);所述氢气还原炉(1)用于采用氢气将铁矿原料还原为直接还原铁;所述气体供应与循环系统与氢气还原炉(1)连接,用于对氢气还原炉(1)提供氢气;所述高温冶炼炉(16)通过密封输送装置(15)与氢气还原炉(1)连接,所述密封输送装置(15)用于将直接还原铁输入送高温冶炼炉(16)。本发明氢冶金系统适用于环保的绿色冶炼工艺。

The present invention relates to a nearly zero emission hydrogen metallurgical system, belonging to the field of metallurgical technology, which solves the problems of large amounts of exhaust gas, solid waste, and environmental pollution emitted by steel smelting in existing technologies. The hydrogen metallurgical system of the present invention includes a hydrogen reduction furnace (1), a gas supply and circulation system, a sealed conveying device (15), and a high-temperature smelting furnace (16); The hydrogen reduction furnace (1) is used to reduce iron ore raw materials to direct reduced iron using hydrogen gas; The gas supply and circulation system is connected to a hydrogen reduction furnace (1) for providing hydrogen gas to the hydrogen reduction furnace (1); The high-temperature smelting furnace (16) is connected to the hydrogen reduction furnace (1) through a sealed conveying device (15), which is used to input direct reduced iron into the high-temperature smelting furnace (16). The hydrogen metallurgical system of the present invention is suitable for environmentally friendly green smelting processes.