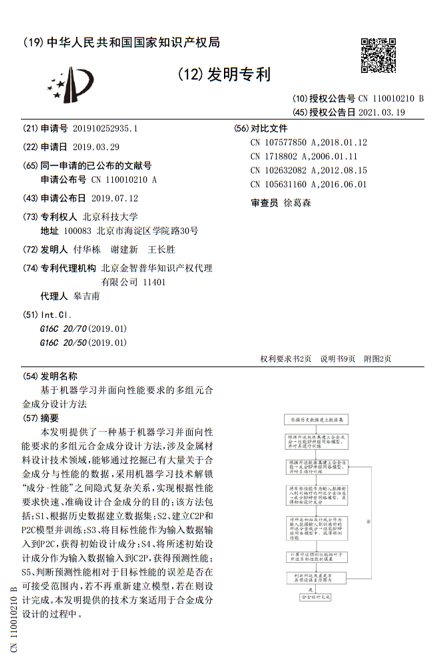

本发明提供了一种基于机器学习并面向性能要求的多组元合金成分设计方法,涉及金属材料设计技术领域,能够通过挖掘已有大量关于合金成分与性能的数据,采用机器学习技术解锁“成分-性能”之间隐式复杂关系,实现根据性能要求快速、准确设计合金成分的目的;该方法包括:S1、根据历史数据建立数据集;S2、建立C2P和P2C模型并训练;S3、将目标性能作为输入数据输入到P2C,获得初始设计成分;S4、将所述初始设计成分作为输入数据输入到C2P,获得预测性能;S5、判断预测性能相对于目标性能的误差是否在可接受范围内,若不再重新建立模型,若在则设计完成。本发明提供的技术方案适用于合金成分设计的过程中。

The present invention provides a multi-component alloy composition design method based on machine learning and oriented to performance requirements. It relates to the technical field of metal material design. It can use machine learning technology to unlock the "composition" by mining a large amount of data about alloy composition and performance. The implicit and complex relationship between "performance" to achieve the purpose of quickly and accurately designing alloy composition according to performance requirements; the method includes: S1,establishing a data set based on historical data; S2,establishing and training C2P and P2C models; S3,setting the target Input performance as input data to P2C to obtain initial design components; S4,Input the initial design components as input data to C2P to obtain prediction performance; S5,Determine whether the error of prediction performance relative to target performance is within an acceptable range, If the model is not re-established, if it is, the design is completed. The technical scheme provided by the present invention is suitable for the process of alloy composition design.