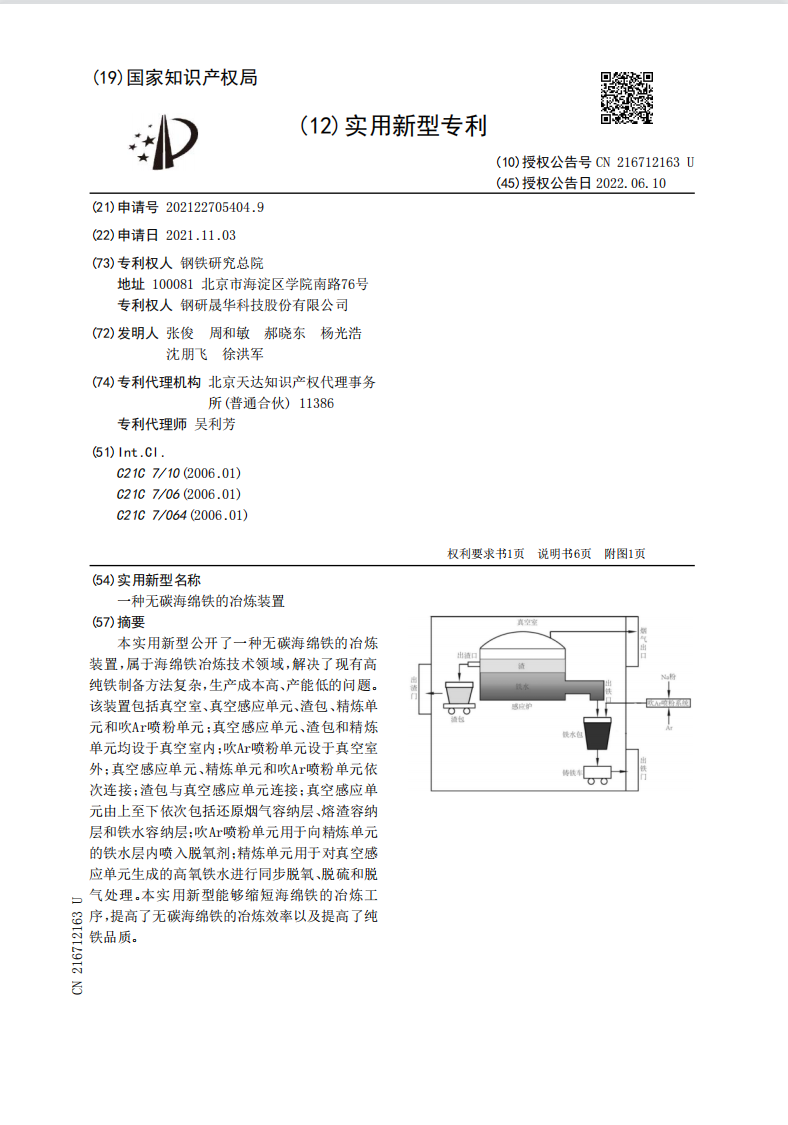

本实用新型公开了一种无碳海绵铁的冶炼装置,属于海绵铁冶炼技术领域,解决了现有高纯铁制备方法复杂,生产成本高、产能低的问题。该装置包括真空室、真空感应单元、渣包、精炼单元和吹Ar喷粉单元;真空感应单元、渣包和精炼单元均设于真空室内;吹Ar喷粉单元设于真空室外;真空感应单元、精炼单元和吹Ar喷粉单元依次连接;渣包与真空感应单元连接;真空感应单元由上至下依次包括还原烟气容纳层、熔渣容纳层和铁水容纳层;吹Ar喷粉单元用于向精炼单元的铁水层内喷入脱氧剂;精炼单元用于对真空感应单元生成的高氧铁水进行同步脱氧、脱硫和脱气处理。本实用新型能够缩短海绵铁的冶炼工序,提高了无碳海绵铁的冶炼效率以及提高了纯铁品质。

This utility model discloses a carbon free sponge iron smelting device, belonging to the field of sponge iron smelting technology, which solves the problems of complex preparation methods, high production costs, and low production capacity of existing high-purity iron. The device includes a vacuum chamber, a vacuum induction unit, a slag ladle, a refining unit, and an Ar blowing and powder spraying unit; The vacuum induction unit, slag ladle, and refining unit are all located in the vacuum chamber; The Ar blowing and powder spraying unit is located outside the vacuum chamber; The vacuum induction unit, refining unit, and Ar blowing and powder spraying unit are sequentially connected; Connection between slag ladle and vacuum induction unit; The vacuum induction unit sequentially includes a reduction flue gas containing layer, a slag containing layer, and a molten iron containing layer from top to bottom; The Ar blowing and powder spraying unit is used to inject deoxidizer into the molten iron layer of the refining unit; The refining unit is used for synchronous deoxidation, desulfurization, and degassing treatment of the high oxygen molten iron generated by the vacuum induction unit. The utility model can shorten the smelting process of sponge iron, improve the smelting efficiency of carbon free sponge iron, and improve the quality of pure iron.