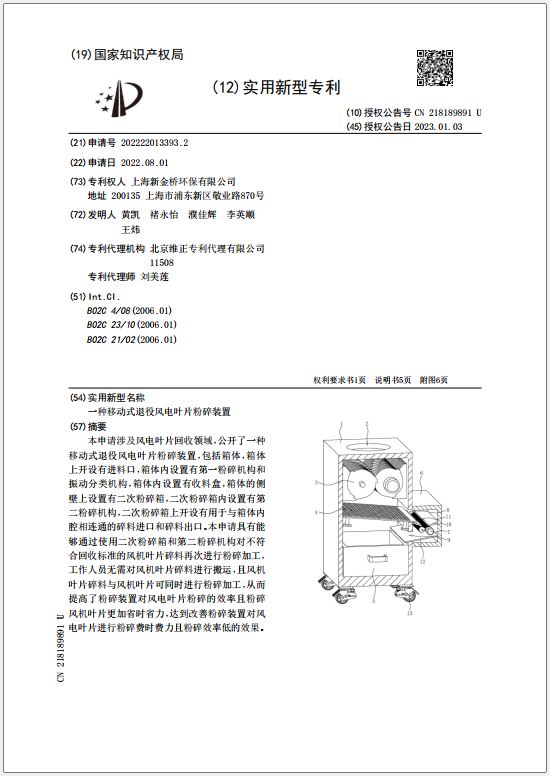

本申请涉及风电叶片回收领域,公开了一种移动式退役风电叶片粉碎装置,包括箱体,箱体上开设有进料口,箱体内设置有第一粉碎机构和振动分类机构,箱体内设置有收料盒,箱体的侧壁上设置有二次粉碎箱,二次粉碎箱内设置有第二粉碎机构,二次粉碎箱上开设有用于与箱体内腔相连通的碎料进口和碎料出口。本申请具有能够通过使用二次粉碎箱和第二粉碎机构对不符合回收标准的风机叶片碎料再次进行粉碎加工,工作人员无需对风机叶片碎料进行搬运,且风机叶片碎料与风机叶片可同时进行粉碎加工,从而提高了粉碎装置对风电叶片粉碎的效率且粉碎风机叶片更加省时省力,达到改善粉碎装置对风电叶片进行粉碎费时费力且粉碎效率低的效果。

This application relates to the field of wind turbine blade recycling and discloses a mobile retired wind turbine blade crushing device, which includes a box body with a feeding port, a first crushing mechanism and a vibration classification mechanism inside the box body, a material receiving box inside the box body, a secondary crushing box on the side wall of the box body, and a second crushing mechanism inside the secondary crushing box, The secondary crushing box is equipped with a crushing inlet and a crushing outlet for communicating with the inner cavity of the box. This application is capable of using a secondary crushing box and a secondary crushing mechanism to crush and process the broken materials of the fan blades that do not meet the recycling standards again. The staff does not need to transport the broken materials of the fan blades, and the broken materials of the fan blades and the fan blades can be crushed and processed simultaneously, thereby improving the efficiency of the crushing device for the wind turbine blades and making the crushing of the fan blades more time-saving and labor-saving, To achieve the effect of improving the crushing device's time-consuming, labor-intensive and low crushing efficiency for wind turbine blades.