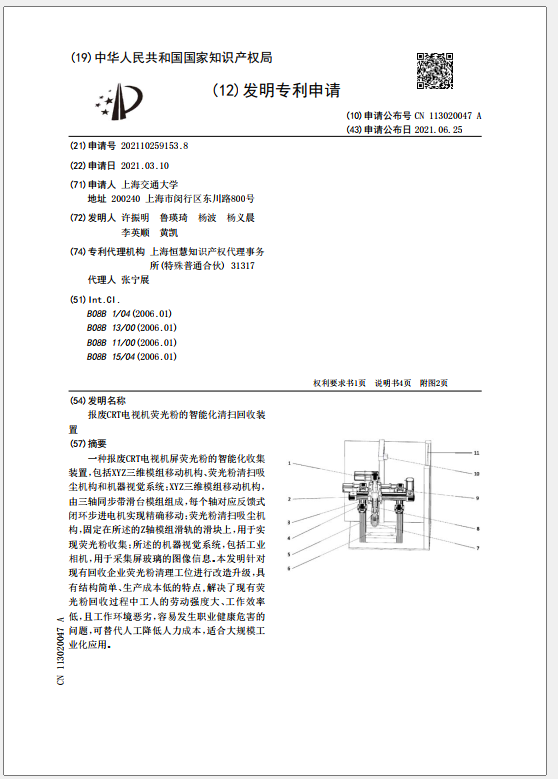

一种报废CRT电视机屏荧光粉的智能化收集装置,包括XYZ三维模组移动机构、荧光粉清扫吸尘机构和机器视觉系统;XYZ三维模组移动机构,由三轴同步带滑台模组组成,每个轴对应反馈式闭环步进电机实现精确移动;荧光粉清扫吸尘机构,固定在所述的Z轴模组滑轨的滑块上,用于实现荧光粉收集;所述的机器视觉系统,包括工业相机,用于采集屏玻璃的图像信息。本发明针对现有回收企业荧光粉清理工位进行改造升级,具有结构简单、生产成本低的特点 ,解决了现有荧光粉回收过程中工人的劳动强度大、工作效率低,且工作环境恶劣,容易发生职业健康危害的问题,可替代人工降低人力成本,适合大规模工业化应用。

An intelligent collection device for discarded CRT television screen phosphors, comprising an XYZ three-dimensional module moving mechanism, a phosphor cleaning and vacuum mechanism, and a machine vision system; XYZ three-dimensional module moving mechanism is composed of three-axis Timing belt sliding table module, and each axis corresponds to a feedback closed-loop stepping motor to achieve accurate movement; The fluorescent powder cleaning and vacuum mechanism is fixed on the slider of the Z-axis module slide rail for achieving fluorescent powder collection; The machine vision system, including an industrial camera, is used to collect image information of screen glass. The present invention aims to renovate and upgrade the fluorescent powder cleaning station of existing recycling enterprises, which has the characteristics of simple structure and low production cost. It solves the problems of high labor intensity, low work efficiency, poor working environment, and easy occurrence of occupational health hazards for workers in the existing fluorescent powder recycling process. It can replace manual labor to reduce labor costs and is suitable for large-scale industrial applications.