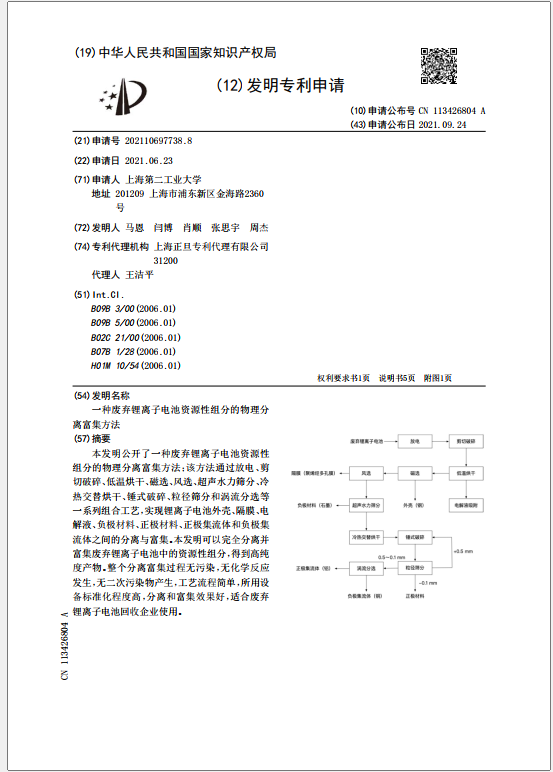

本发明公开了一种废弃锂离子电池资源性组分的物理分离富集方法;该方法通过放电、剪切破碎、低温烘干、磁选、风选、超声水力筛分、冷热交替烘干、锤式破碎、粒径筛分和涡流分选等一系列组合工艺,实现锂离子电池外壳、隔膜、电解液、负极材料、正极材料、正极集流体和负极集流体之间的分离与富集。本发明可以完全分离并富集废弃锂离子电池中的资源性组分,得到高纯度产物。整个分离富集过程无污染,无化学反应发生,无二次污染物产生,工艺流程简单,所用设备标准化程度高,分离和富集效果好,适合废弃锂离子电池回收企业使用。

The present invention discloses a physical separation and enrichment method for resource components of discarded lithium-ion batteries; This method achieves separation and enrichment between the shell, separator, electrolyte, negative electrode material, positive electrode material, positive electrode current collector, and negative electrode current collector of lithium-ion batteries through a series of combined processes such as discharge, shear crushing, low-temperature drying, magnetic separation, air separation, ultrasonic hydraulic screening, alternating cold and hot drying, hammer crushing, particle size screening, and eddy current sorting. The present invention can completely separate and enrich the resource components in waste lithium-ion batteries to obtain high-purity products. The entire separation and enrichment process is pollution-free, free from chemical reactions, and free from secondary pollutants. The process flow is simple, the equipment used is highly standardized, and the separation and enrichment effect is good. It is suitable for use by waste lithium-ion battery recycling enterprises.