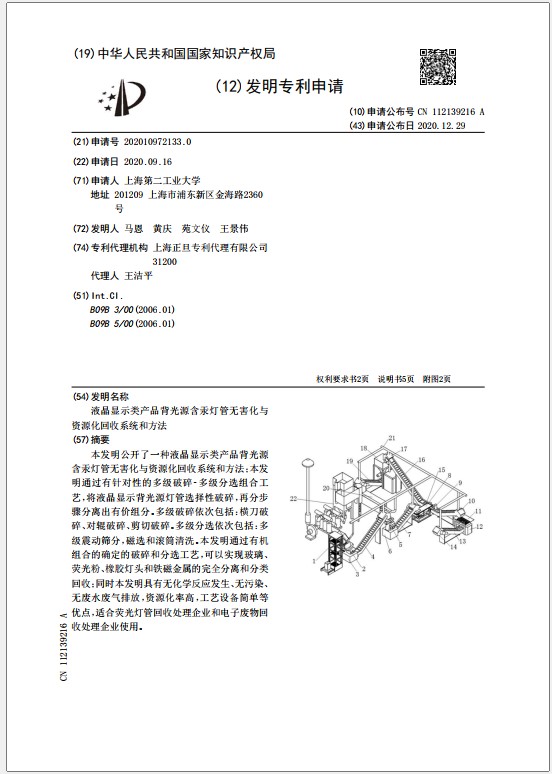

本发明公开了一种液晶显示类产品背光源含汞灯管无害化与资源化回收系统和方法;本发明通过有针对性的多级破碎‑多级分选组合工艺,将液晶显示背光源灯管选择性破碎,再分步骤分离出有价组分。多级破碎依次包括:横刀破碎、对辊破碎、剪切破碎。多级分选依次包括:多级震动筛分,磁选和滚筒清洗。本发明通过有机组合的确定的破碎和分选工艺,可以实现玻璃、荧光粉、橡胶灯头和铁磁金属的完全分离和分类回收;同时本发明具有无化学反应发生、无污染、无废水废气排放,资源化率高,工艺设备简单等优点,适合荧光灯管回收处理企业和电子废物回收处理企业使用。

The present invention discloses a harmless and resource recovery system and method for a mercury containing lamp tube in a back light source of a liquid crystal display product; The present invention selectively crushes the LCD backlight lamp tube through a targeted multi-stage crushing multi-stage sorting combination process, and then separates valuable components in steps. Multi stage crushing includes: horizontal knife crushing, roller crushing, and shear crushing. The multi-level sorting sequence includes: multi-level vibration screening, magnetic separation, and drum cleaning. The present invention can achieve complete separation and classified recycling of glass, fluorescent powder, rubber lamp caps, and ferromagnetic metals through an organic combination of determined crushing and sorting processes; At the same time, the present invention has the advantages of no chemical reaction, no pollution, no wastewater or exhaust emissions, high resource utilization rate, simple process equipment, etc., and is suitable for use by fluorescent lamp tube recycling and electronic waste recycling and treatment enterprises.