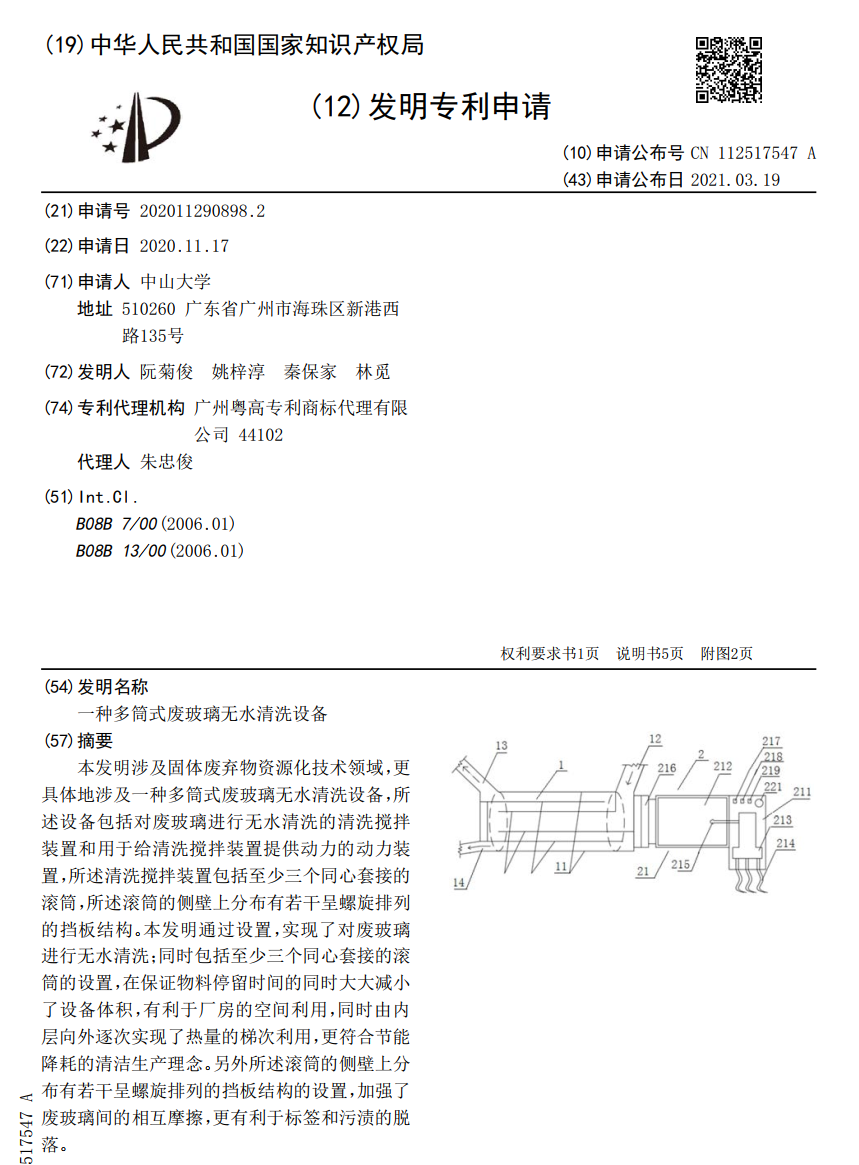

本发明涉及固体废弃物资源化技术领域,更具体地涉及一种多筒式废玻璃无水清洗设备,所述设备包括对废玻璃进行无水清洗的清洗搅拌装置和用于给清洗搅拌装置提供动力的动力装置,所述清洗搅拌装置包括至少三个同心套接的滚筒,所述滚筒的侧壁上分布有若干呈螺旋排列的挡板结构。本发明通过设置,实现了对废玻璃进行无水清洗;同时包括至少三个同心套接的滚筒的设置,在保证物料停留时间的同时大大减小了设备体积,有利于厂房的空间利用,同时由内层向外逐次实现了热量的梯次利用,更符合节能降耗的清洁生产理念。另外所述滚筒的侧壁上分布有若干呈螺旋排列的挡板结构的设置,加强了废玻璃间的相互摩擦,更有利于标签和污渍的脱落。

The invention relates to the technical field of solid waste recycling, and more specifically to a multi-cylinder type waterless cleaning equipment for waste glass. The equipment comprises a cleaning stirring device for waterless cleaning of waste glass and a power device for powering a cleaning stirring device. The cleaning stirring device comprises at least three concentrically connected drums. A plurality of screw-arranged baffle structures are distributed on the side wall of the drum. The invention realizes waterless cleaning of waste glass by setting; At the same time, it includes at least three concentrically connected rollers, which greatly reduces the volume of equipment while ensuring the residence time of materials, which is conducive to the utilization of the space of the workshop. At the same time, it realizes the step utilization of heat successively from the inner layer to the outer layer, which is more in line with the cleaner production concept of energy saving and consumption reduction. In addition, a number of screw-arranged baffle structures are arranged on the side wall of the roller, which strengthens the mutual friction between the waste glass and is more conducive to the shedding of labels and stains.