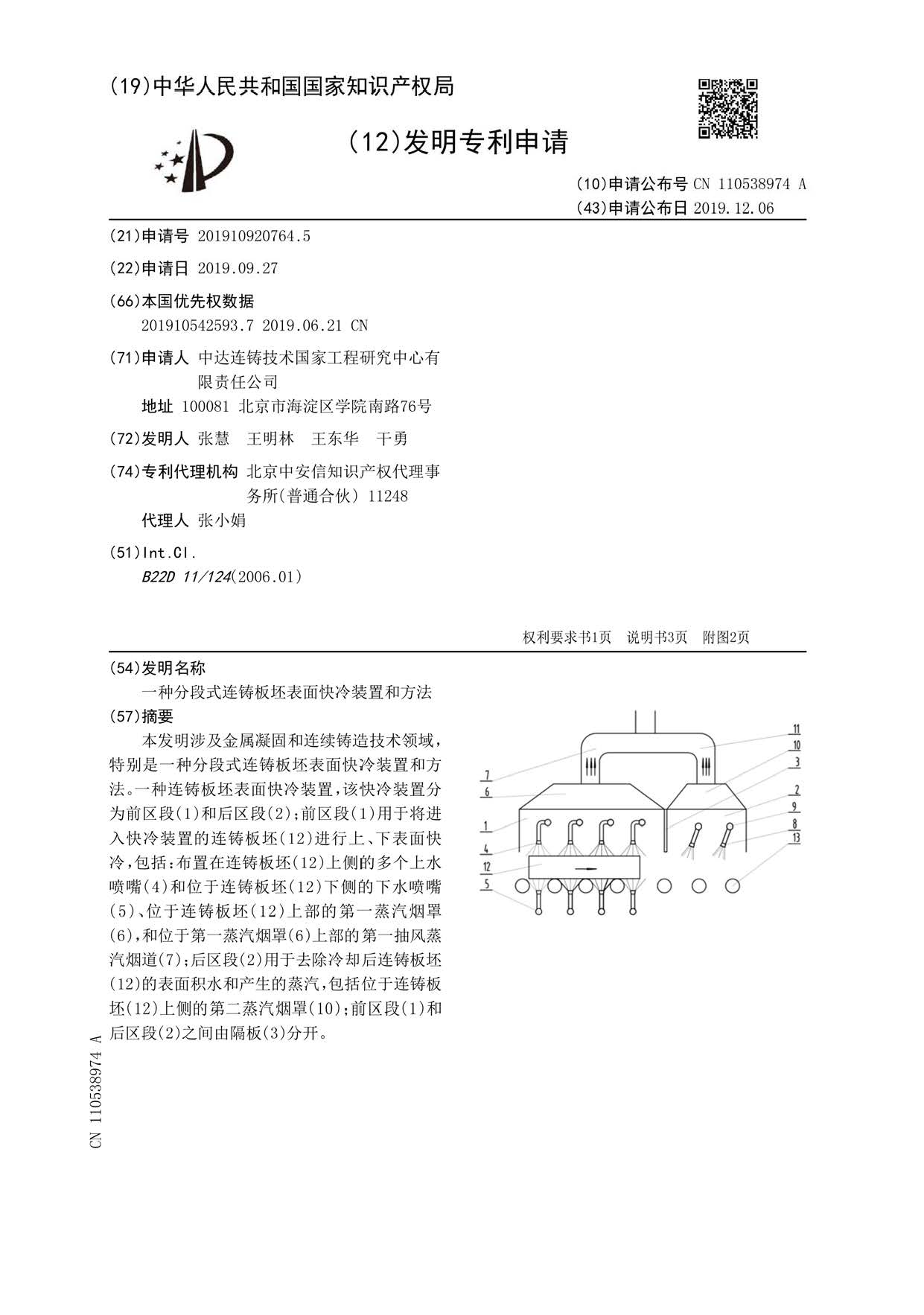

本发明涉及金属凝固和连续铸造技术领域,特别是一种分段式连铸板坯表面快冷装置和方法。一种连铸板坯表面快冷装置,该快冷装置分为前区段(1)和后区段(2);前区段(1)用于将进入快冷装置的连铸板坯(12)进行上、下表面快冷,包括:布置在连铸板坯(12)上侧的多个上水喷嘴(4)和位于连铸板坯(12)下侧的下水喷嘴(5)、位于连铸板坯(12)上部的第一蒸汽烟罩(6),和位于第一蒸汽烟罩(6)上部的第一抽风蒸汽烟道(7);后区段(2)用于去除冷却后连铸板坯(12)的表面积水和产生的蒸汽,包括位于连铸板坯(12)上侧的第二蒸汽烟罩(10);前区段(1)和后区段(2)之间由隔板(3)分开。

The present invention relates to the field of metal solidification and continuous casting technology, in particular, a segmented continuous casting slab surface quick-cooling device and method. A continuous casting slab surface quick-cooling device, which is divided into a front section (1) and a rear section (2); the front section (1) is used to quick-cool the upper and lower surfaces of the continuous casting slab (12) entering the quick-cooling device, including: a plurality of upper water nozzles (4) arranged on the upper side of the continuous casting slab (12) and lower water nozzles (5) located on the lower side of the continuous casting slab (12), a first steam fume hood (6) located on the upper side of the continuous casting slab (12), and a The first steam fume hood (6) located on the upper side of the continuous casting slab (12), and the first extract steam flue (7) located on the upper side of the first steam fume hood (6); the rear section (2) is used to remove water and steam generated on the surface of the continuous casting slab (12) after cooling, and includes a second steam fume hood (10) located on the upper side of the continuous casting slab (12); the front section (1) and the rear section (2) are separated by a partition (3).