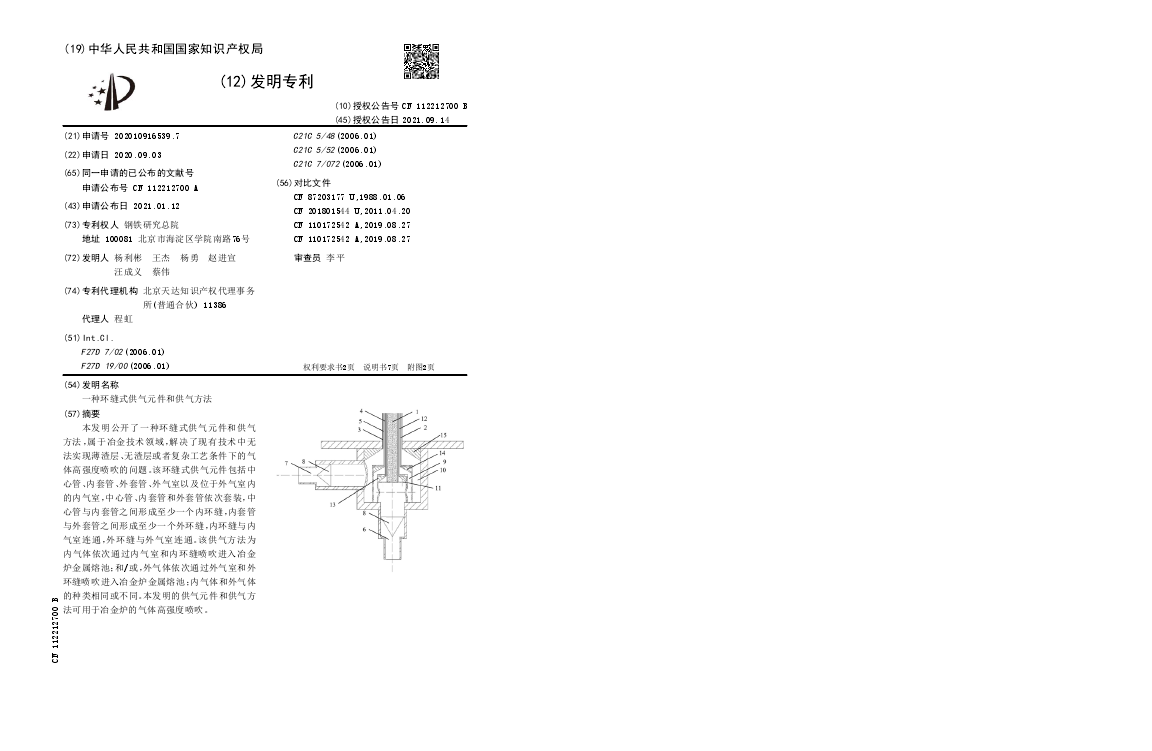

本发明公开了一种环缝式供气元件和供气方法,属于冶金技术领域,解决了现有技术中无法实现薄渣层、无渣层或者复杂工艺条件下的气体高强度喷吹的问题。该环缝式供气元件包括中心管、内套管、外套管、外气室以及位于外气室内的内气室,中心管、内套管和外套管依次套装,中心管与内套管之间形成至少一个内环缝,内套管与外套管之间形成至少一个外环缝,内环缝与内气室连通,外环缝与外气室连通。该供气方法为内气体依次通过内气室和内环缝喷吹进入冶金炉金属熔池;和/或,外气体依次通过外气室和外环缝喷吹进入冶金炉金属熔池;内气体和外气体的种类相同或不同。本发明的供气元件和供气方法可用于冶金炉的气体高强度喷吹。

The invention discloses a ring slit type gas supply element and a gas supply method, belonging to the field of metallurgical technology, and solves the problem that the existing technology cannot realize high strength gas injection under thin slag layer, slagless layer or complex process conditions. The annular gas supply element comprises a central tube, an inner casing, an outer casing, an outer gas chamber and an inner gas chamber located in an outer gas chamber. The central tube, the inner casing and the outer casing are arranged sequentially. At least one inner annular gap is formed between the central tube and the inner casing, and at least one outer annular gap is formed between the inner casing and the outer casing. The inner annular gap is connected with the inner gas chamber, and the outer annular gap is connected with the outer gas chamber. The gas supply method is that the inner gas is successively injected into the metal molten pool of the metallurgical furnace through the inner chamber and the inner ring gap; and / or, the external gas is injected into the metal molten pool of the metallurgical furnace through the external chamber and the external ring joint in turn; the types of internal and external gases are the same or different. The gas supply element and method of the invention can be used for high strength gas injection in metallurgical furnace.