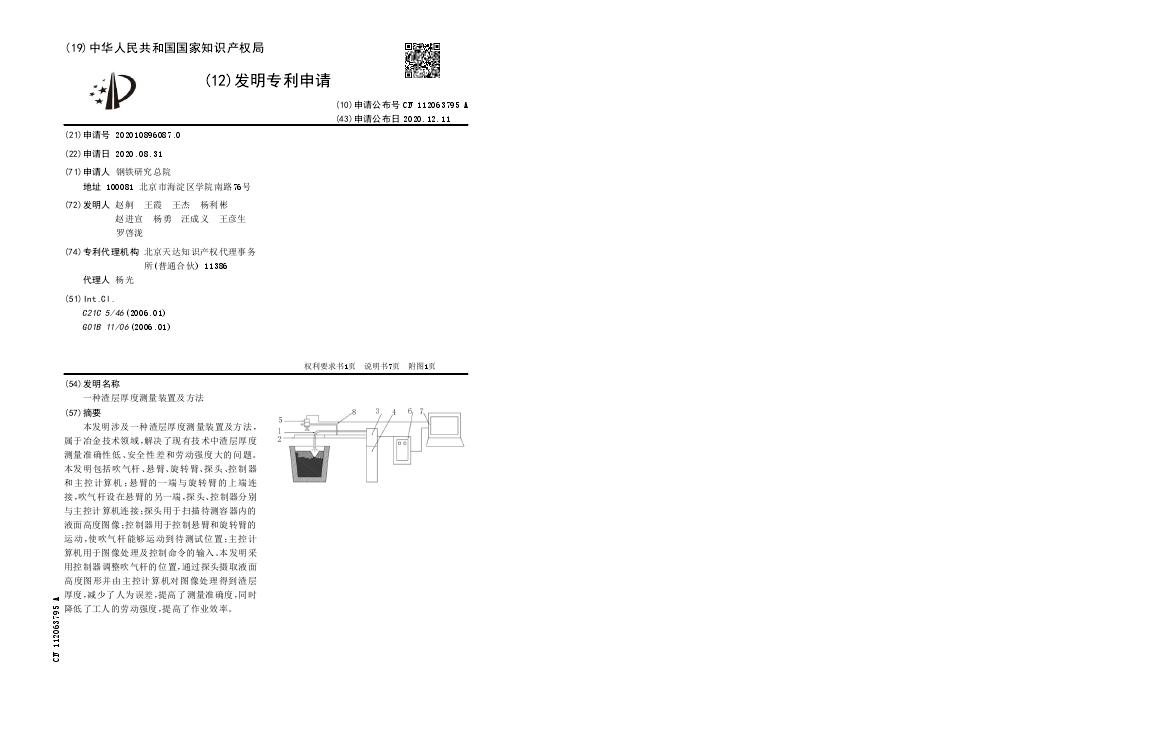

本发明涉及一种渣层厚度测量装置及方法,属于冶金技术领域,解决了现有技术中渣层厚度测量准确性低、安全性差和劳动强度大的问题。本发明包括吹气杆、悬臂、旋转臂、探头、控制器和主控计算机;悬臂的一端与旋转臂的上端连接,吹气杆设在悬臂的另一端,探头、控制器分别与主控计算机连接;探头用于扫描待测容器内的液面高度图像;控制器用于控制悬臂和旋转臂的运动,使吹气杆能够运动到待测试位置;主控计算机用于图像处理及控制命令的输入。本发明采用控制器调整吹气杆的位置,通过探头摄取液面高度图形并由主控计算机对图像处理得到渣层厚度,减少了人为误差,提高了测量准确度,同时降低了工人的劳动强度,提高了作业效率。

The invention relates to a slag layer thickness measuring device and method, which is in the field of metallurgical technology, solving problems with low accuracy, poor safety and labor intensity in the existing technique thickness measurement. The invention includes blowing rods, cantilever, rotating arms, probes, controllers, and master computers; One end of the cantilever is connected to the upper end of the rotating arm, and the blowing rod is located at the other end of the cantilever, the probe, the controller connected to the master computer, respectively; Probes for scanning liquid levels in the container to be tested; the controller is used to control the movement of the cantilever and the rotating arm, so that the blower can move to the position to be tested; the master computer is used to input the image processing and control command. The invention adopts the controller to adjust the position of the blowing rod, by the probe tight level, and by the master computer to obtain a slag layer thickness, reduce the human error, improve the measurement accuracy, while reducing the labor intensity of workers Increase job efficiency.