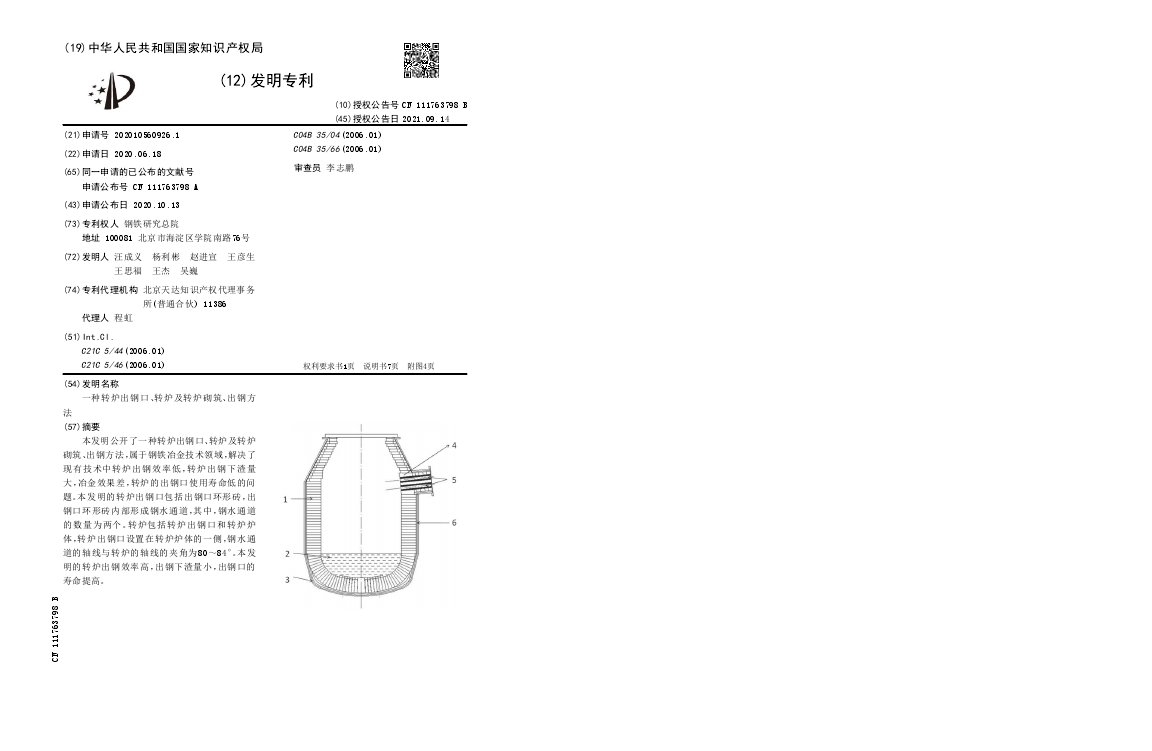

本发明公开了一种转炉出钢口、转炉及转炉砌筑、出钢方法,属于钢铁冶金技术领域,解决了现有技术中转炉出钢效率低,转炉出钢下渣量大,冶金效果差,转炉的出钢口使用寿命低的问题。本发明的转炉出钢口包括出钢口环形砖,出钢口环形砖内部形成钢水通道,其中,钢水通道的数量为两个。转炉包括转炉出钢口和转炉炉体,转炉出钢口设置在转炉炉体的一侧,钢水通道的轴线与转炉的轴线的夹角为80~84°。本发明的转炉出钢效率高,出钢下渣量小,出钢口的寿命提高。

The invention publics a tap hole of converters, converters and masonry of converters, a method for tapping, which belongs to the field of iron and steel metallurgical technology, and solves the problems of low effect for tapping of converters, large slag quantity for tapping of converters, poor metallurgical effect and low service life of tap hole of converters in the prior art. The tap hole of converters in the invention includes the ring brick of tap hole, and the ring brick of tap hole forms the molten steel channels inside, among which the number of molten steel channels is two. A converter comprises a tap hole and a body of converters. The tap hole of converters is arranged on one side of the body of converters. The included Angle between the axis of molten steel channel and the axis of the converter is 80 ~ 84°. The converter of the invention has high efficiency of tapping, small slag quantity for tapping and long service life of tap hole.