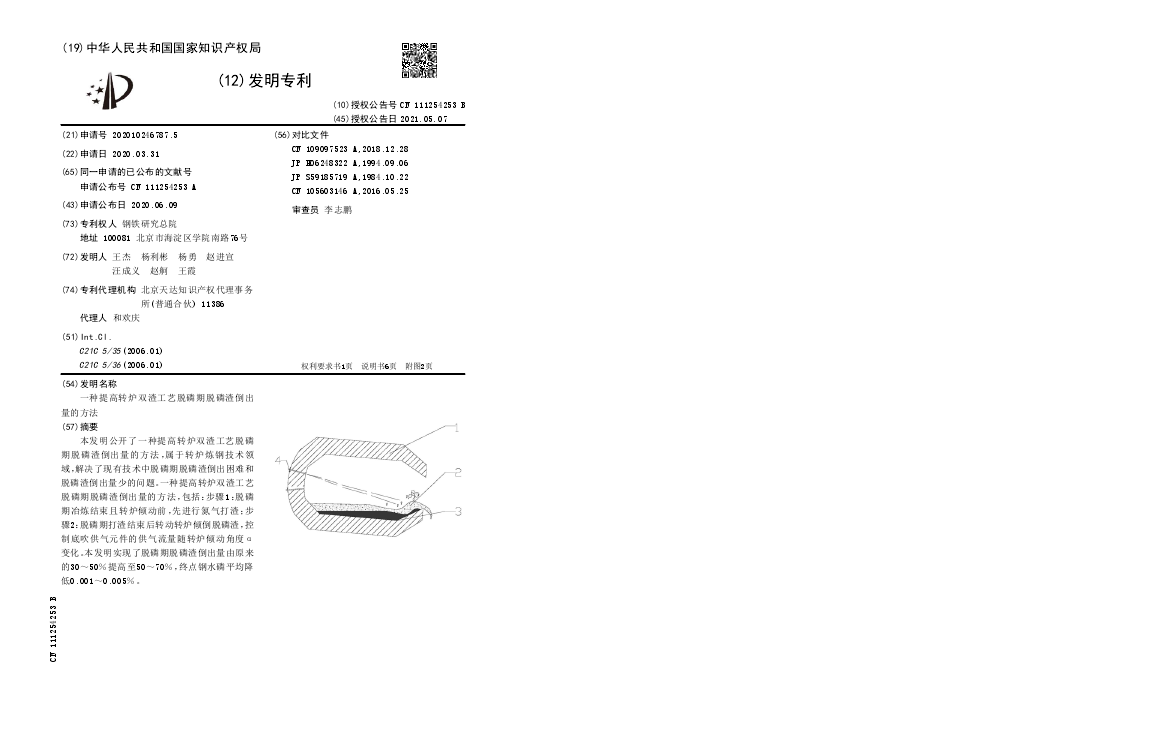

本发明公开了一种提高转炉双渣工艺脱磷期脱磷渣倒出量的方法,属于转炉炼钢技术领域,解决了现有技术中脱磷期脱磷渣倒出困难和脱磷渣倒出量少的问题。一种提高转炉双渣工艺脱磷期脱磷渣倒出量的方法,包括:步骤1:脱磷期冶炼结束且转炉倾动前,先进行氮气打渣;步骤2:脱磷期打渣结束后转动转炉倾倒脱磷渣,控制底吹供气元件的供气流量随转炉倾动角度α变化。本发明实现了脱磷期脱磷渣倒出量由原来的30~50%提高至50~70%,终点钢水磷平均降低0.001~0.005%。

The invention discloses a method of improving the amount of dephosphorus residue during dephosphorization of the converter double slag process, which belongs to the field of converter steelmaking, solving the difficulty of dumping dephosphorus slag during dephosphorization and problem of the less amount of dephosphorus residue. The method for improving the amount of dephosphorus slag dumped during dephosphorization of the converter double slag process, including: Step 1: After the smelting of the dephosphorized period, the Nitrogen slag is in front of the conversion; Step 2: After the dephosphorization period, the convection of the converter pouring the dewing residue, the gas supply flow rate of the bottom blown air supply element is changed with the convection angleα. The invention achieves the amount of dephosphorus slag dumped during dephosphorization period by the original 30 to 50% to 50 to 70%, and the average of the end-point steel phosphorus is 0.001 to 0.005%.