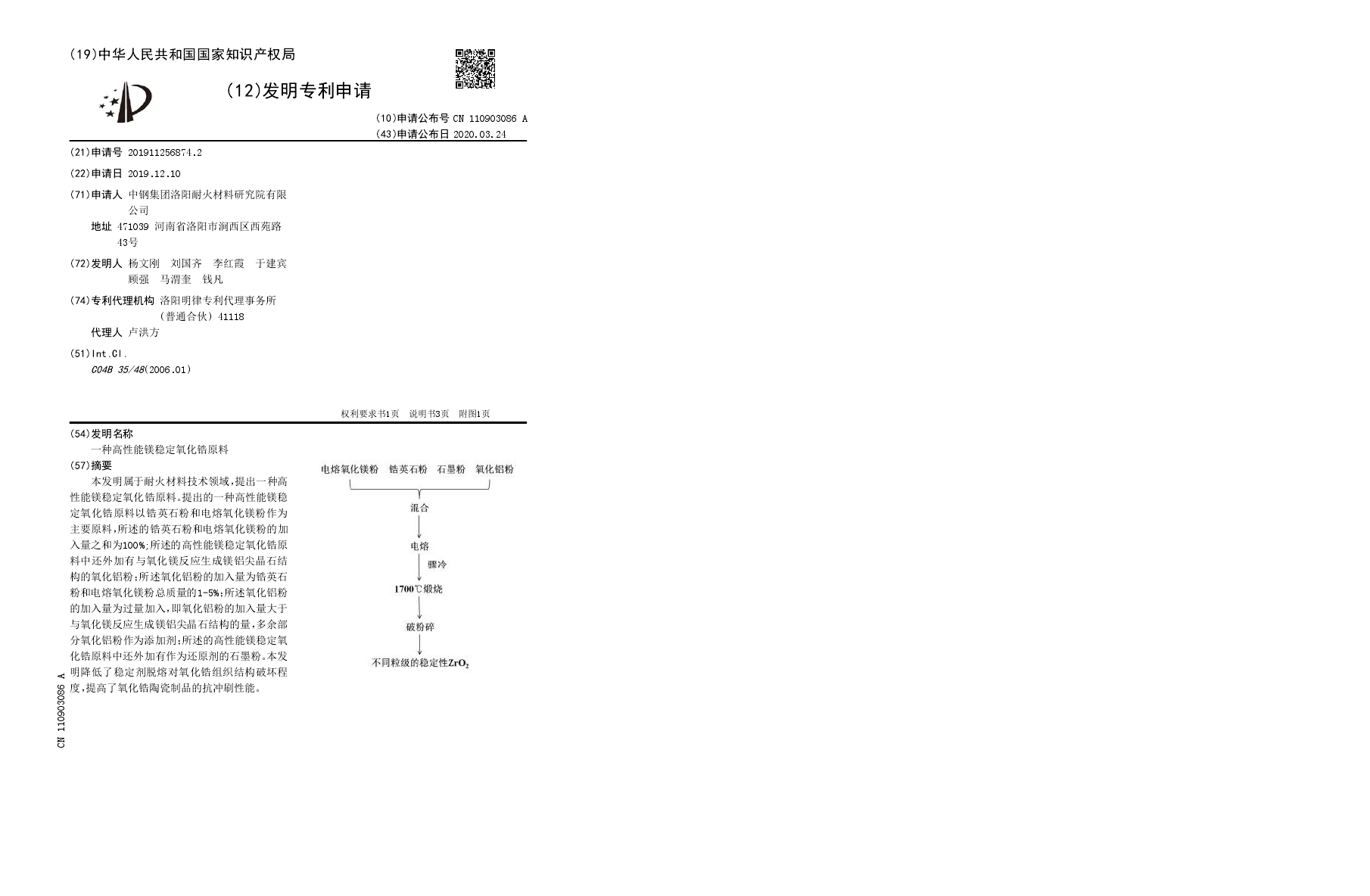

本发明属于耐火材料技术领域,提出一种高性能镁稳定氧化锆原料。提出的一种高性能镁稳定氧化锆原料以锆英石粉和电熔氧化镁粉作为主要原料,所述的锆英石粉和电熔氧化镁粉的加入量之和为100%;所述的高性能镁稳定氧化锆原料中还外加有与氧化镁反应生成镁铝尖晶石结构的氧化铝粉;所述氧化铝粉的加入量为锆英石粉和电熔氧化镁粉总质量的1-5%;所述氧化铝粉的加入量为过量加入,即氧化铝粉的加入量大于与氧化镁反应生成镁铝尖晶石结构的量,多余部分氧化铝粉作为添加剂;所述的高性能镁稳定氧化锆原料中还外加有作为还原剂的石墨粉。本发明降低了稳定剂脱熔对氧化锆组织结构破坏程度,提高了氧化锆陶瓷制品的抗冲刷性能。

The invention belongs to the technical field of refractory materials, and a high- performance magnesium stabilized zirconia raw material is proposed. For the high performance raw material of magnesium stabilized zirconia proposed, zircon powder and fused magnesia powder are used as the main raw materials, and the sum of zircon powder and fused magnesia powder is 100%; the high performance magnesium stabilized zirconia raw material is also added with alumina powder which reacts with magnesium oxide to form magnesium aluminum spinel structure; the addition amount of alumina powder is 1-5% of the total mass of zircon powder and fused magnesia powder; the addition amount of alumina powder is excessive, that is, the addition amount of alumina powder is greater than the amount of magnesia alumina spinel structure formed by reaction with magnesium oxide, and the excess alumina powder is used as an additive; the high performance magnesium stabilized zirconia raw materials are also added with graphite powder as reducing agent. The invention reduces the damage degree of stabilizer demelting to zirconia microstructure and improves the anti-erosion performance of zirconia ceramic products.