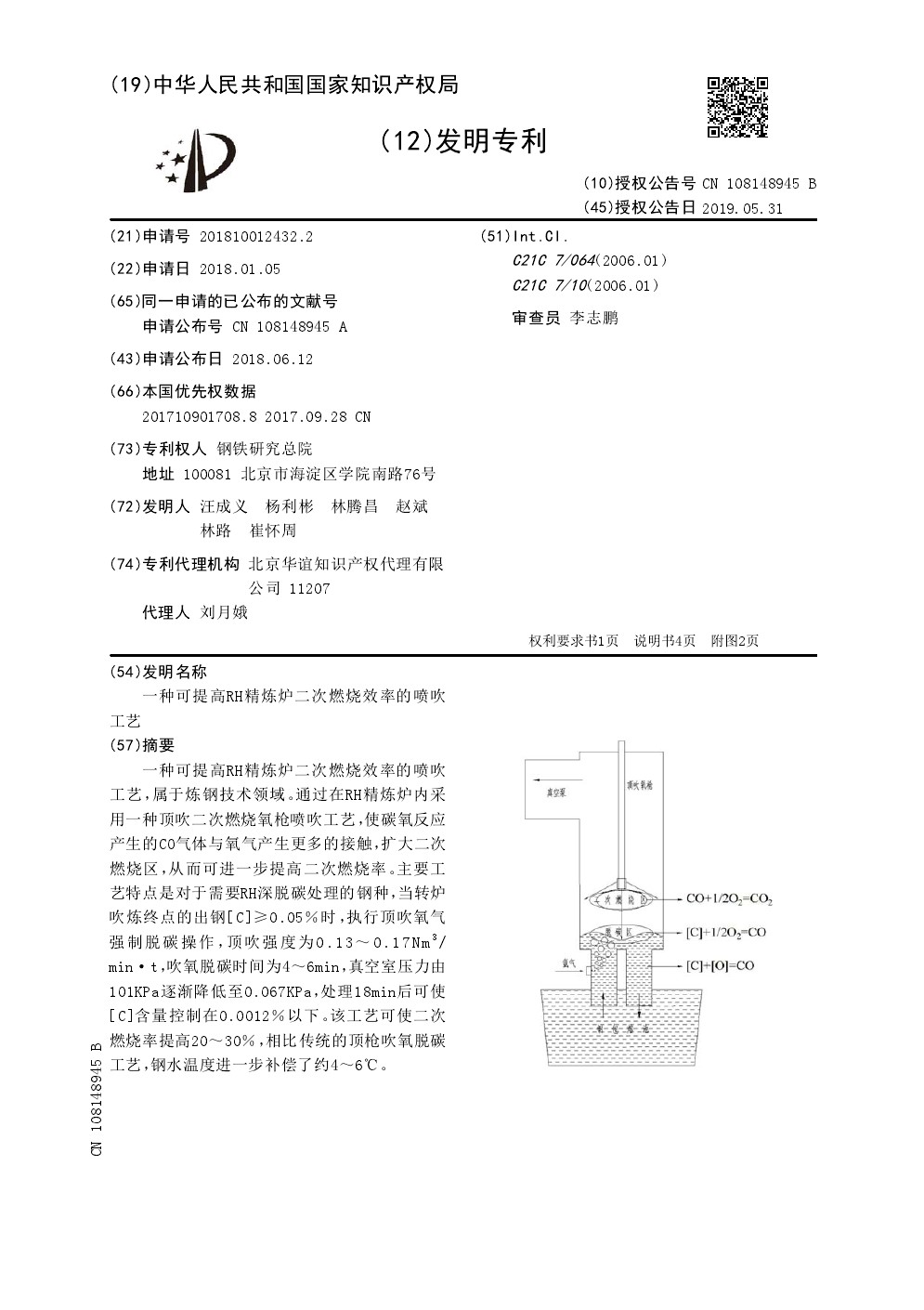

一种可提高RH精炼炉二次燃烧效率的喷吹工艺,属于炼钢技术领域。通过在RH精炼炉内采用一种顶吹二次燃烧氧枪喷吹工艺,使碳氧反应产生的CO气体与氧气产生更多的接触,扩大二次燃烧区,从而可进一步提高二次燃烧率。主要工艺特点是对于需要RH深脱碳处理的钢种,当转炉吹炼终点的出钢[C]≥0.05%时,执行顶吹氧气强制脱碳操作,顶吹强度为0 .13~0 .17Nm3/min·t,吹氧脱碳时间为4~6min,真空室压力由101KPa逐渐降低至0.067KPa,处理18min后可使[C]含量控制在0.0012%以下。该工艺可使二次燃烧率提高20~30%,相比传统的顶枪吹氧脱碳工艺,钢水温度进一步补偿了约4~6℃。

An injection process capable of improving the secondary combustion efficiency of RH refining furnace,belonging to the technical field of steelmaking.By adopting a top-blown secondary combustion oxygen lance injection process in RH refining furnace, the CO gas produced by carbon-oxygen reaction can be in more contact with oxygen, and the secondary combustion zone is enlarged, thereby further improving the secondary combustion rate.The main process feature is that for steel grades requiring RH deep decarburization treatment, when the tapping [C] at the end of converter blowing is ≥0.05% , the top-blowing oxygen forced decarburization operation is performed, the top blowing intensity is 0.13~0.17Nm3/min·t, the oxygen blowing decarbonization time is 4~6min, the vacuum chamber pressure is gradually reduced from 101kpa to 0.067kpa, and the [C] content can be controlled below 0.0012% after treatment for 18min.This process can increase the secondary combustion rate by 20~30%. Compared with the traditional top gun oxygen blowing decarbonization process, the molten steel temperature is further compensated by about 4~6 ℃。