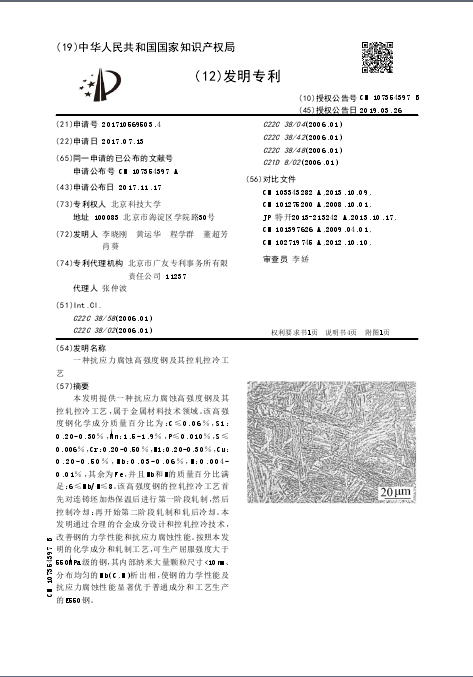

本发明提供一种抗应力腐蚀高强度钢及其控轧控冷工艺,属于金属材料技术领域。该高强度钢化学成分质量百分比为:C≤0.06%,Si:0.20-0.30%,Mn:1.5-1.9%,P≤0.010%,S≤0.006%,Cr:0.20-0.50%,Ni:0.20-0.30%,Cu:0.20-0.50%,Nb:0.03-0.06%,N:0.004-0.01%,其余为Fe,并且Nb和N的质量百分比满足:6≤Nb/N≤8。该高强度钢的控轧控冷工艺首先对连铸坯加热保温后进行第一阶段轧制,然后控制冷却:再开始第二阶段轧制和轧后冷却。本发明通过合理的合金成分设计和控轧控冷技术,改善钢的力学性能和抗应力腐蚀性能。按照本发明的化学成分和轧制工艺,可生产屈服强度大于550MPa级的钢,其内部纳米大量颗粒尺寸<10nm、分布均匀的Nb(C,N)析出相,使钢的力学性能及抗应力腐蚀性能显著优于普通成分和工艺生产的E550钢。

The present invention provides a stress corrosion resistant high strength steel and its controlled rolling and cooling process, which belongs to the technical field of metal materials. The chemical composition of the high-strength steel is: C≤0.06%, Si: 0.20-0.30%, Mn: 1.5-1.9%, P≤0.010%, S≤0.006%, Cr: 0.20-0.50%, Ni: 0.20-0.30%, Cu: 0.20-0.50%, Nb: 0.03-0.06%, N. The controlled rolling and cooling process of this high-strength steel starts with the heating and holding of the continuous casting billet for the first stage of rolling, followed by controlled cooling: then the second stage of rolling and post-rolling cooling is started. The invention is designed to improve the mechanical properties and stress corrosion resistance of the steel by means of a reasonable alloy composition and controlled rolling and cooling technology. According to the chemical composition and rolling process of the invention, it is possible to produce steel with yield strength greater than 550 MPa, with a large number of internal Nb(C,N) precipitation phases with particle size <10 nm and uniform distribution, which makes the mechanical properties and stress corrosion resistance of the steel significantly better than those of E550 steel produced by common composition and process.