Atomically thin sheets of hexagonal boron nitride (h-BN) have the handy benefit of protecting what’s underneath from oxidizing even at very high temperatures, Rice University researchers have discovered.

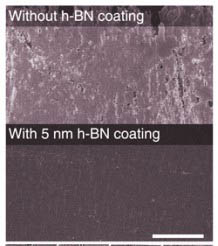

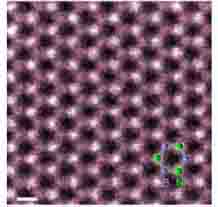

Rice University researchers have discovered that sheets of hexagonal boron nitride (h-BN) as little as one atom thick can protect metals in harsh environments at up to 1,100 degrees Celsius. The top image of the first image shows uncoated nickel oxidized after exposure to high temperature in an oxygen-rich environment. The second shows nickel exposed to the same conditions with a 5-nanometer coat of h-BN. The middle image shows electron microscope images of two, three, four and many-layer h-BN films. The last image of an h-BN sheet shows the hexagonal arrangement of nitrogen (bright) and boron atoms. Images by Zheng Liu

One or several layers of the material sometimes called “white graphene” keep materials from oxidizing – or rusting — up to 1,100 degrees Celsius (2,012 degrees Fahrenheit), and can be made large enough for industrial applications, they said.

The Rice study led by materials scientists Pulickel Ajayan and Jun Lou appears in the online journal Nature Communications.

Oxidation prevention is already big business, but no products available now work on the scale of what the Rice lab is proposing. The researchers see potential for very large sheets of h-BN only a few atoms thick made by scalable vapor deposition methods.

“We think this opens up new opportunities for two-dimensional material,” said Lou, an associate professor of mechanical engineering and materials science. “Everybody has been talking about these materials for electronic or photonic devices, but if this can be realized on a large scale, it’s going to cover a broad spectrum of applications.”

Lou said ultrathin h-BN protection might find a place in turbines, jet engines, oil exploration or underwater or other harsh environments where minimal size and weight would be an advantage, though wear and abrasion could become an issue and optimum thicknesses need to be worked out for specific applications.

It’s effectively invisible as well, which may make it useful for protecting solar cells from the elements, he said. “Essentially, this can be a very useful structural material coating,” Lou said.

The researchers made small sheets of h-BN via chemical vapor deposition (CVD), a process they said should be scalable for industrial production. They first grew the thin material on nickel foil and found it withstood high temperature in an oxygen-rich environment. They also grew h-BN on graphene and found they could transfer sheets of h-BN to copper and steel with similar results.

“What’s amazing is that these layers are ultrathin and they stand up to such ultrahigh temperatures,” Ajayan said. “At a few nanometers wide, they’re a totally non-invasive coating. They take almost no space at all.”

Lead authors are Rice postdoctoral researcher Zheng Liu and graduate student Yongji Gong. Co-authors are Rice graduate student Lulu Ma and Senior Faculty Fellow Robert Vajtai; Wu Zhou, a Wigner Fellow, and Juan Carlos Idrobo, a staff scientist at Oak Ridge National Laboratory; Jingjiang Yu of Agilent Technologies; Jeil Jung, a research fellow at the National University of Singapore and a postdoctoral researcher at the University of Texas at Austin; and Allan MacDonald, the Sid W. Richardson Foundation Regents Chair Professor at the University of Texas at Austin. Ajayan is the Benjamin M. and Mary Greenwood Anderson Professor in Mechanical Engineering and Materials Science and of chemistry at Rice.

The Army Research Office, the Office of Naval Research, the Welch Foundation, the Korean Institute of Machinery and Materials, the National Science Foundation, Oak Ridge National Laboratory and the Department of Energy supported the research.