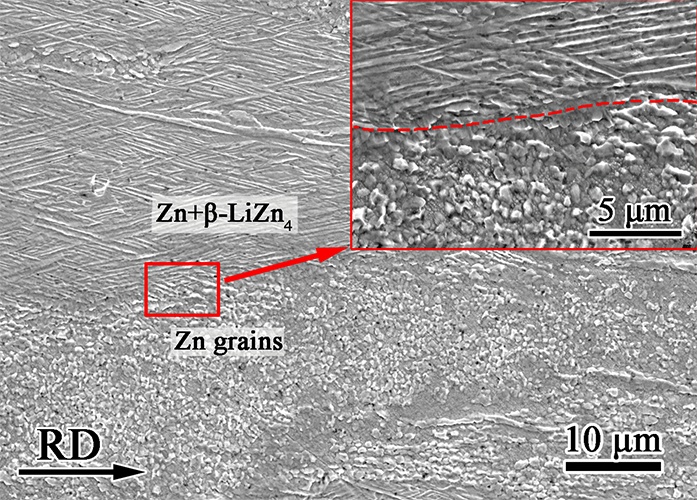

轧制态合金由细晶Zn相和细长的β-LiZn4带组成,并有针状Zn析出,如图3(a)所示。两针状Zn析出相之间的平均宽度为0.44±0.06μm,比铸态减少约35%。从图3(a)的插入图中可以看出,Zn晶粒较细,平均尺寸在0.3 ~ 0.7μm之间。从图3(a)的插入图中可以看出,Zn晶粒较细,平均尺寸在0.3 ~ 0.7μm之间,图3(b)的TEM表征也证实了这一点。热轧处理显著细化了Zn晶粒,使粗大的初生β-LiZn4枝晶转变为长条形枝晶,强度和塑性均显著提高。

The as-rolled alloy is composed of fine-grained Zn phase and elongated β-LiZn4 bands with needle-like Zn precipitates, as shown in Fig. 3(a). The average width between two needle-like Zn precipitates is 0.44 ± 0.06μm, about 35% less than that in the as-cast alloy. As can be seen in the insert figure in Fig. 3(a), Zn grains are fine, with an average size ranged from 0.3μm to 0.7μm, which is confirmed by TEM characterization in Fig. 3(b). The hot-warm rolling significantly refines Zn grains and changes the coarse primary β-LiZn4 dendrites into elongated bands, resulting in the dramatic increase in both the strength and the ductility.As can be seen in the insert figure in Fig. 3(a), Zn grains are fine, with an average size ranged from 0.3μm to 0.7μm, which is confirmed by TEM characterization in Fig. 3(b). The hot-warm rolling significantly refines Zn grains and changes the coarse primary β-LiZn4 dendrites into elongated bands, resulting in the dramatic increase in both the strength and the ductility.