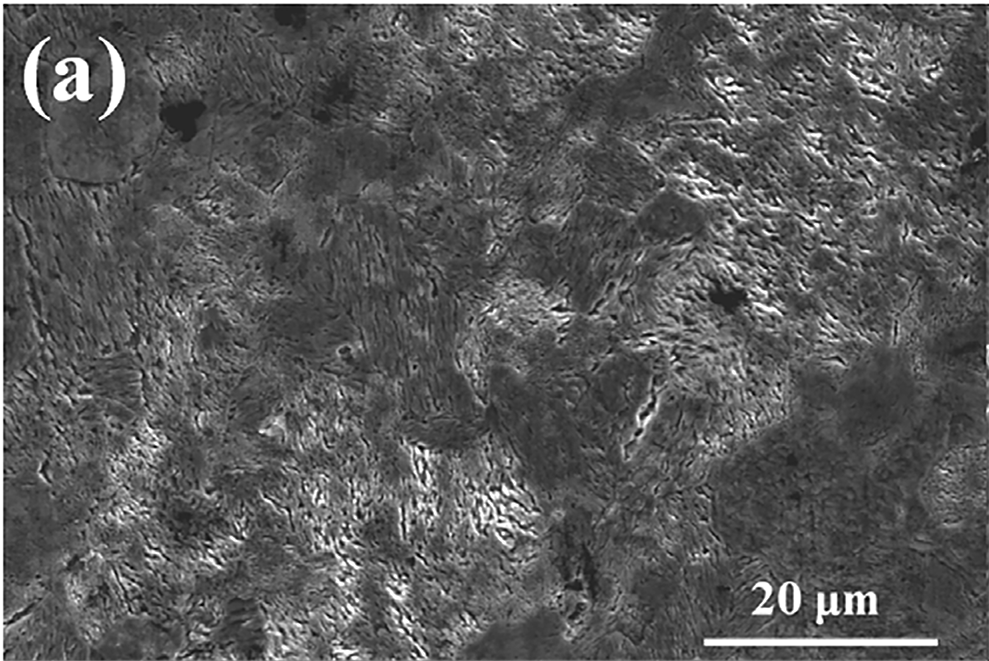

图8显示了纯锌样品在盐水溶液中浸泡并去除腐蚀产物后的光学图像,以揭示下面的腐蚀侵蚀。俯视图显示锌腐蚀均匀。在整个表面上均匀进行的腐蚀侵蚀和产物形成。然而,似乎可以观察到一些空隙(图8b和c),表明在盐水溶液中浸泡后有局部腐蚀的趋势。Boshkov等人报告称,氯离子(Cl)参与了反应,在矿坑及其邻近区域形成氢氧化锌氯化物。盐溶液中的局部腐蚀与锌的体外试验研究结果一致。程等报道了纯锌在汉克溶液中局部腐蚀的情况下受到侵蚀;和陈等人报道了锌在PBS中浸泡21 d后在产物层下呈现明显的空洞/孔和槽状形貌。我们的结果证实了纯锌在含Cl-溶液中浸泡后可能会发生局部腐蚀。因此,纯锌在实际应用中可能不是一种有前途的材料。然而,合金设计可能是增强锌的局部耐腐蚀性的一种有前途的方法

Fig. 8 shows optical images of pure Zn samples after soaking in saline solution and removing the corrosion product in order to unveil the underneath corrosion attack. The top view showed uniform corrosion on zinc. Corrosion attack and products formation that undertook homogenously on the whole surface. However, it seems that some voids could be observed (Fig. 8b and c), indicating a tendency of localized corrosion after immersion in saline solution. Boshkov et al. reported that chloride ions (Cl−) participated in the reaction to form zinc hydroxide chloride in the pits and their neighborhood areas. And the localized corrosion in saline solution was in accordance with some research about the in vitro test of Zn. Cheng et al.reported that pure Zn was attacked under localized corrosion in Hank's solution; and Chen et al. reported that Zn presented apparently cavity/hole- and groove-like morphology underneath the product layer after immersion in PBS for 21 d. Our results confirmed that pure Zn may encounter localized corrosion after immersion in Cl−containing solution. Thus, pure Zn may not be a promising material for practical application.However, alloy design may be a promising approach to enhance the localized corrosion resistance of zinc.