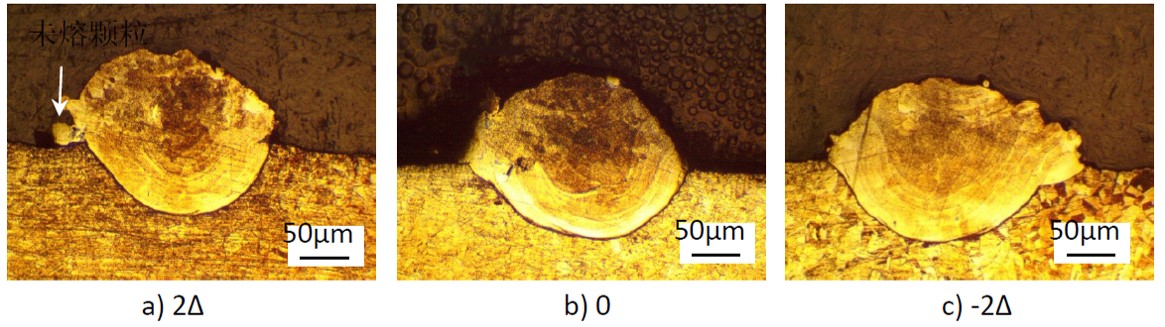

可见,2Δ状态下的熔覆层外表面相对-2Δ状态下的熔覆层外表面更加不平整,表面有些未完全熔化的粉末颗粒。这是因为粉束流在下落过程中会产生一定的发散角,在负离焦状态下环形激光束对粉束流时刻处于一种包覆状态,即使处于发散位置的粉末颗粒也可以受到激光束的辐照。但正离焦状态下的激光束在会聚位置被包覆在了粉束流的内部,因此在熔池内会有一部分因吸能不足、熔化不充分的粉末颗粒粘接在熔覆层的外表面,这就使得正离焦状态下形成的熔覆层粗糙度较大。

The outer surface of the molten layer in the 2Δ state is more uneven than the outer surface of the molten layer in the -2Δ state, and some powder particles are not completely melted on the surface. In the negative defocus state, the annular laser beam is always in an enveloping state, and the powder particles in the defocus position can be irradiated by the laser beam. However, the laser beam in the positive defocus state is wrapped inside the powder beam stream at the convergence position, so there will be part of the powder particles that are not sufficiently melted due to insufficient energy absorption in the melt pool bonded to the outer surface of the melt layer, which makes the roughness of the melt layer formed in the positive defocus state larger.