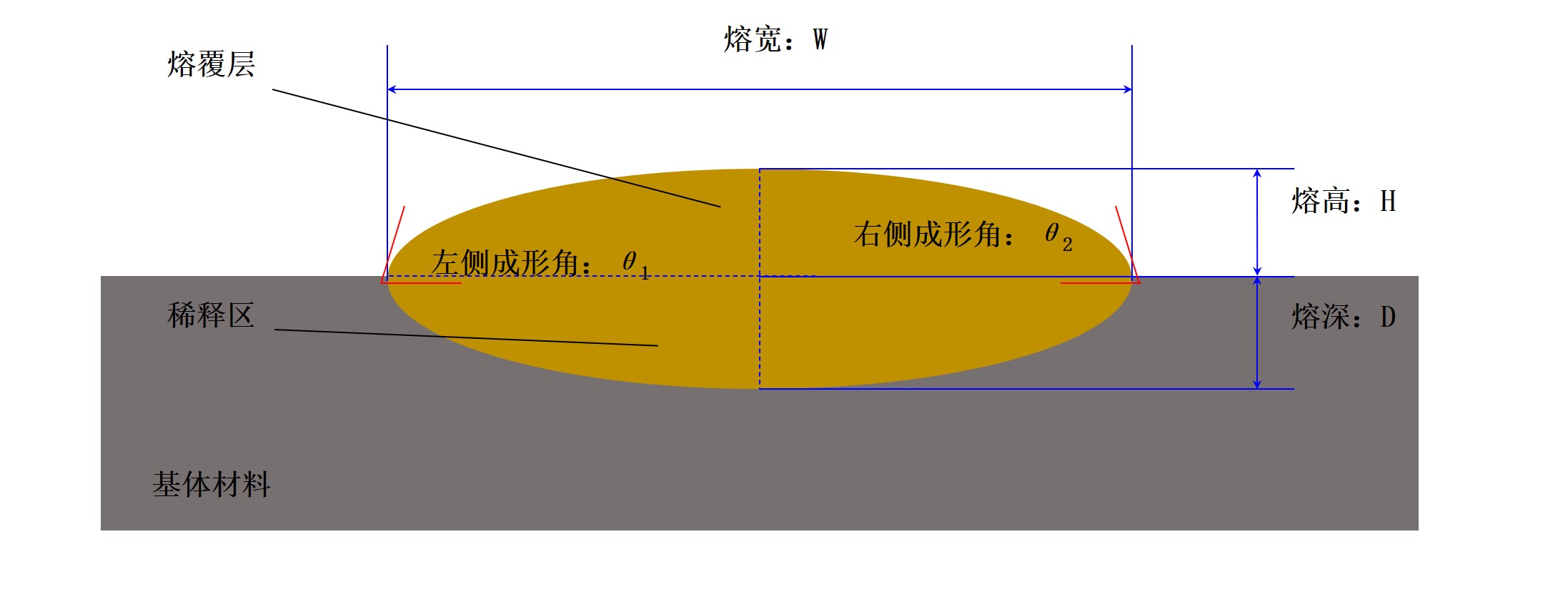

图3分别为单道熔覆层的宏观形貌和金相形貌。由图 a)可知,熔覆层的外表面没有粘接未熔粉末颗粒,熔覆层的表面光滑平整。由图b)可知,熔覆层的熔宽为400.8μm,熔高为200.8μm,熔覆层宽高比为1.99。可见环形光内同轴中心送粉熔覆过程中送粉管位于激光束的几何中心,实现了光粉同轴耦合的目标。由于粉束垂直喷射,所以粉束流不存在汇聚焦点,但受环境气氛影响,粉束流在喷射过程中会有一定的发散,但在环形保护气的作用下,粉束可以被充分包裹在环形气帘内部。通过对粉管直径和聚焦光斑负离焦量的调节,粉束流可以完全被激光束包覆,进而光粉耦合过程很大程度上不会出现粉末散落在激光外侧的情况。从图 中可以看到熔覆层的外表面不仅光滑,而且熔覆层整体立体感更强。

Figure 3 shows the macroscopic and metallographic morphology of the single-pass cladding layer, respectively. From Fig. a), it can be seen that the outer surface of the clad layer is free of unbonded powder particles and the surface of the clad layer is smooth and flat. It can be seen from Fig. b) that the melt width of the clad layer is 400.8 μm, the melt height is 200.8 μm, and the width-to-height ratio of the clad layer is 1.99. It can be seen that the powder feeding tube is located in the geometric center of the laser beam during the coaxial powder feeding process in the ring light, which achieves the goal of coaxial coupling of the light and powder. Since the powder beam is injected vertically, there is no convergence focus of the powder beam flow, but the powder beam flow is affected by the ambient atmosphere, there will be some dispersion during the injection process, but the powder beam can be fully wrapped inside the annular air curtain under the action of the annular protective gas. By adjusting the diameter of the powder tube and the negative defocusing amount of the focusing spot, the powder beam stream can be completely wrapped by the laser beam, and thus the optical-powder coupling process is largely free of powder scattering on the outside of the laser. As can be seen in the figure, the outer surface of the clad layer is not only smooth, but also has a stronger overall three-dimensional appearance.