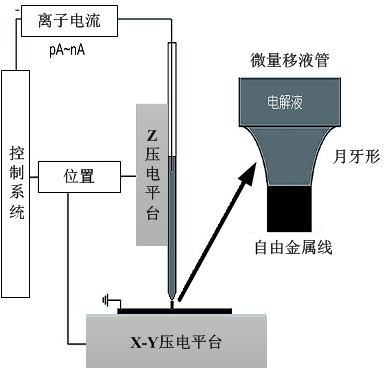

MCED的工作原理为:在微移液管(内含不溶性导电微丝体、出口直径100 nm至数微米)出口与阴极间形成连续稳定的弯液面(微液桥),并使在电场作用下弯液面内的金属离子还原为原子并堆积在阴极上,在此过程中,实时控制出液量、电流量、移液管三维微移动方向与移动量等参数,以获得所设计的三维微结构体(如图)

MCED works on the principle of forming a continuous and stable curved liquid surface (micro-liquid bridge) between the outlet of the micro-pipette (containing insoluble conductive micro-filaments, outlet diameter 100 nm to several microns) and the cathode, and causing the metal ions in the curved liquid surface to reduce to atoms and accumulate on the cathode under the action of electric field, in this process, real-time control of liquid discharge, electric flow, three-dimensional micro-moving direction of the pipette and the amount of movement and other parameters to obtain the designed three-dimensional micro-structured body (as shown in the figure)