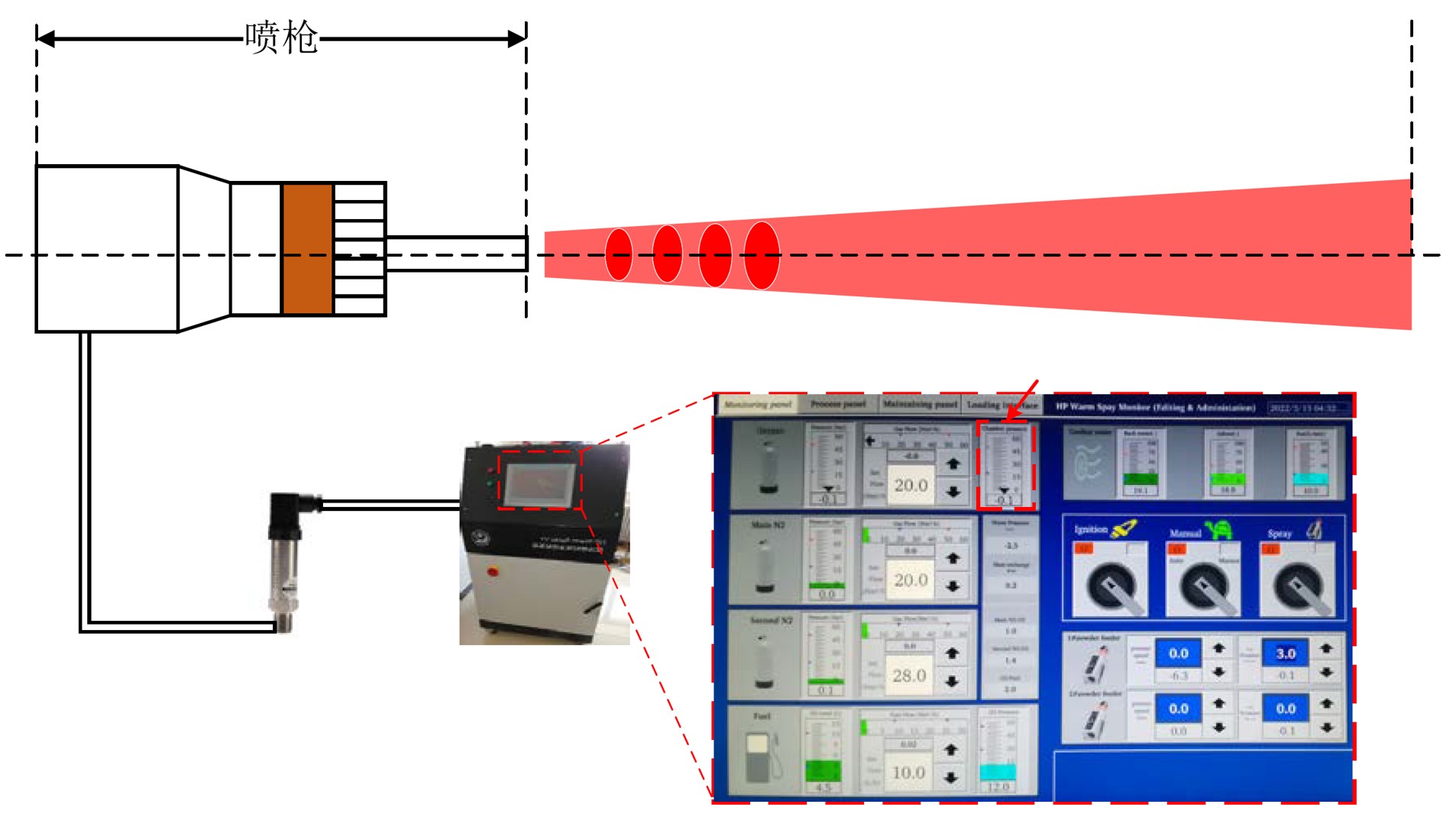

燃烧室压力测量原理如图所示,用铜管从燃烧室内部引出高温、高压气体,并进行一段距离的散热降温处理,最后将气体通入压力变送器。压力变送器将被测的压力按照一定的规律转换成可输出的电信号,并将电信号反馈至控制柜进行处理,在控制柜的监控界面可以监测燃烧室内部的压力值。

The principle of the combustion chamber pressure measurement is shown in the figure. The high-temperature and high-pressure gas is drawn from the inside of the combustion chamber by a copper tube, and the heat dissipation and cooling process is carried out for a certain distance, and finally the gas is passed into the pressure transmitter. The pressure transmitter converts the measured pressure into an output electrical signal according to a certain rule, and feeds the electrical signal back to the control cabinet for processing, and the pressure value inside the combustion chamber can be monitored in the monitoring interface of the control cabinet.