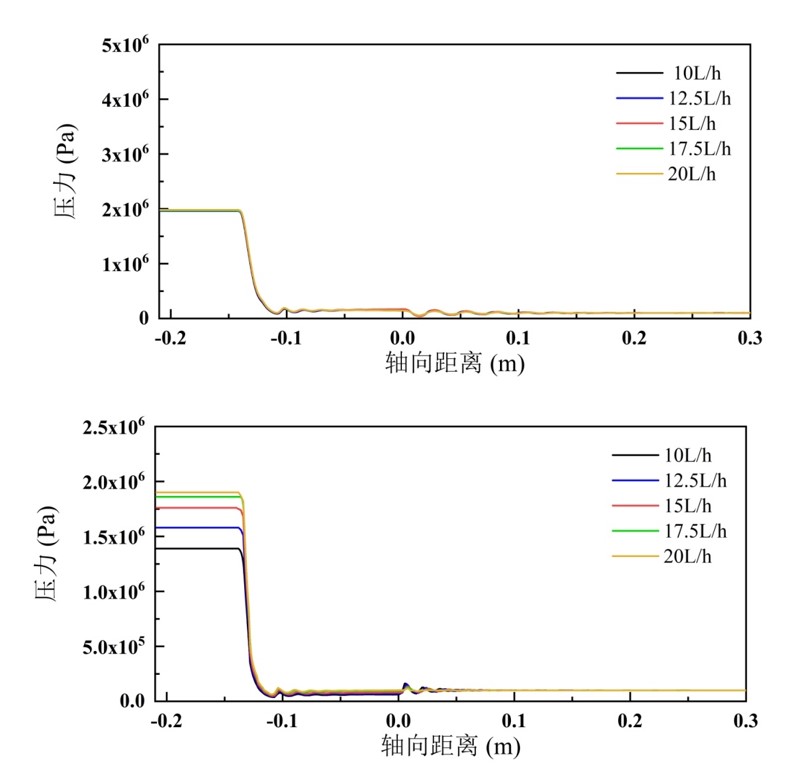

上图表示不同反应物流量下焰流压力与轴向距离的关系,下图表示无一次氮气与二次氮气注入时不同反应物流量下焰流压力与轴向距离的关系。从图中可以看出,在不注入一次氮气和二次氮气时,燃烧室内部的压力随着煤油与氧气流量的增多不断增大,而注入一次氮气和二次氮气时燃烧室内部压力基本维持在1.98MPa左右。这是因为在其他喷涂参数不变的情况下,二次氮气入口面积较大,其注入流量相对较多,焰流压力趋近于二次氮气的注入压力,而导致燃烧室内部压力与油氧流量的变化关系不大。因此,为了避免燃气回流现象的出现,必须要控制一次注氮、二次注氮压力大于该油氧流量下燃烧室内部的初始压力。

The upper graph shows the relationship between flame flow pressure and axial distance at different reactant flow rates, and the lower graph shows the relationship between flame flow pressure and axial distance at different reactant flow rates without primary and secondary nitrogen injection. From the figure, it can be seen that the pressure inside the combustion chamber increases with the increase of kerosene and oxygen flow without primary and secondary nitrogen injection, while the pressure inside the combustion chamber is basically maintained at about 1.98 MPa when primary and secondary nitrogen are injected. This is because in the case of other spraying parameters remain unchanged, the secondary nitrogen inlet area is larger, its injection flow is relatively more, and the flame flow pressure tends to be similar to the secondary nitrogen injection pressure, and the pressure inside the combustion chamber is not much related to the change of oil and oxygen flow. Therefore, in order to avoid the phenomenon of gas reflux, the primary nitrogen injection and secondary nitrogen injection pressure must be controlled to be greater than the initial pressure inside the combustion chamber under this oil-oxygen flow rate.