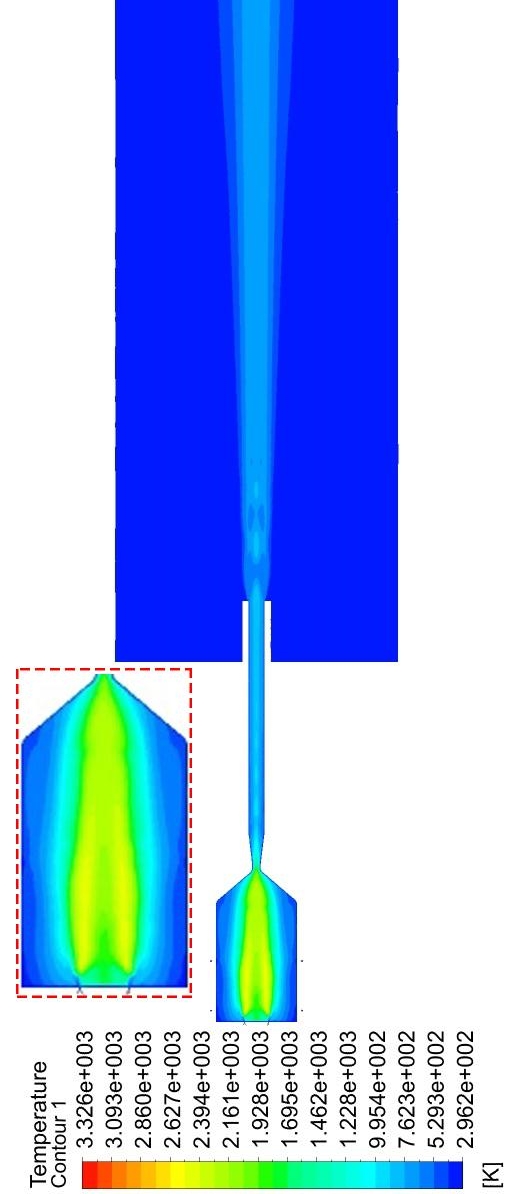

模拟软件使fluent,以2 MPa二次氮气压力为例对焰流温度进行分析,如图所示。由于二次氮气的切向注入,高压氮气将火焰推向燃烧室轴心处,在水冷与氮气的协同降温下焰流温度显著降低,特别是燃烧室近壁面处的气相区域。此外,常温氮气与燃烧气体的掺混主要发生在燃烧室的后半段,随着燃烧室壁面不断的收缩,聚集在壁面处的氮气逐渐向中心推移,最终在拉瓦尔喷嘴喉部处与燃烧产生的气体充分混合。一方面,二次高压氮气切向注入技术不会过早的干预焰流,避免中心焰流温度过低或流动状态不稳定而熄灭火焰;另一方面,二次高压氮气切向注入技术会将焰流推向轴心处,促使煤油与氧气不会向两端过度扩散而导致燃烧室轴心处燃料供给不足。

Simulation software uses“ fluent",The flame flow temperature was analyzed at 2 MPa secondary nitrogen pressure as an example, as shown in the figure. Due to the tangential injection of secondary nitrogen, the high pressure nitrogen pushes the flame to the axial center of the combustion chamber, and the flame flow temperature decreases significantly under the synergistic cooling of water cooling and nitrogen, especially in the gas phase region near the wall of the combustion chamber. In addition, the mixing of room temperature nitrogen and combustion gas mainly occurs in the second half of the combustion chamber, with the continuous contraction of the combustion chamber wall, the nitrogen gathered at the wall gradually pushed to the center, and finally at the throat of the Laval nozzle with the combustion gas fully mixed. On the one hand, the secondary high-pressure nitrogen tangential injection technology will not interfere with the flame flow prematurely to prevent the flame from being extinguished due to the low temperature or unstable flow state of the central flame flow; on the other hand, the secondary high-pressure nitrogen tangential injection technology will push the flame flow to the center of the shaft, so that the kerosene and oxygen will not diffuse excessively to the ends and lead to insufficient fuel supply at the center of the combustion chamber.