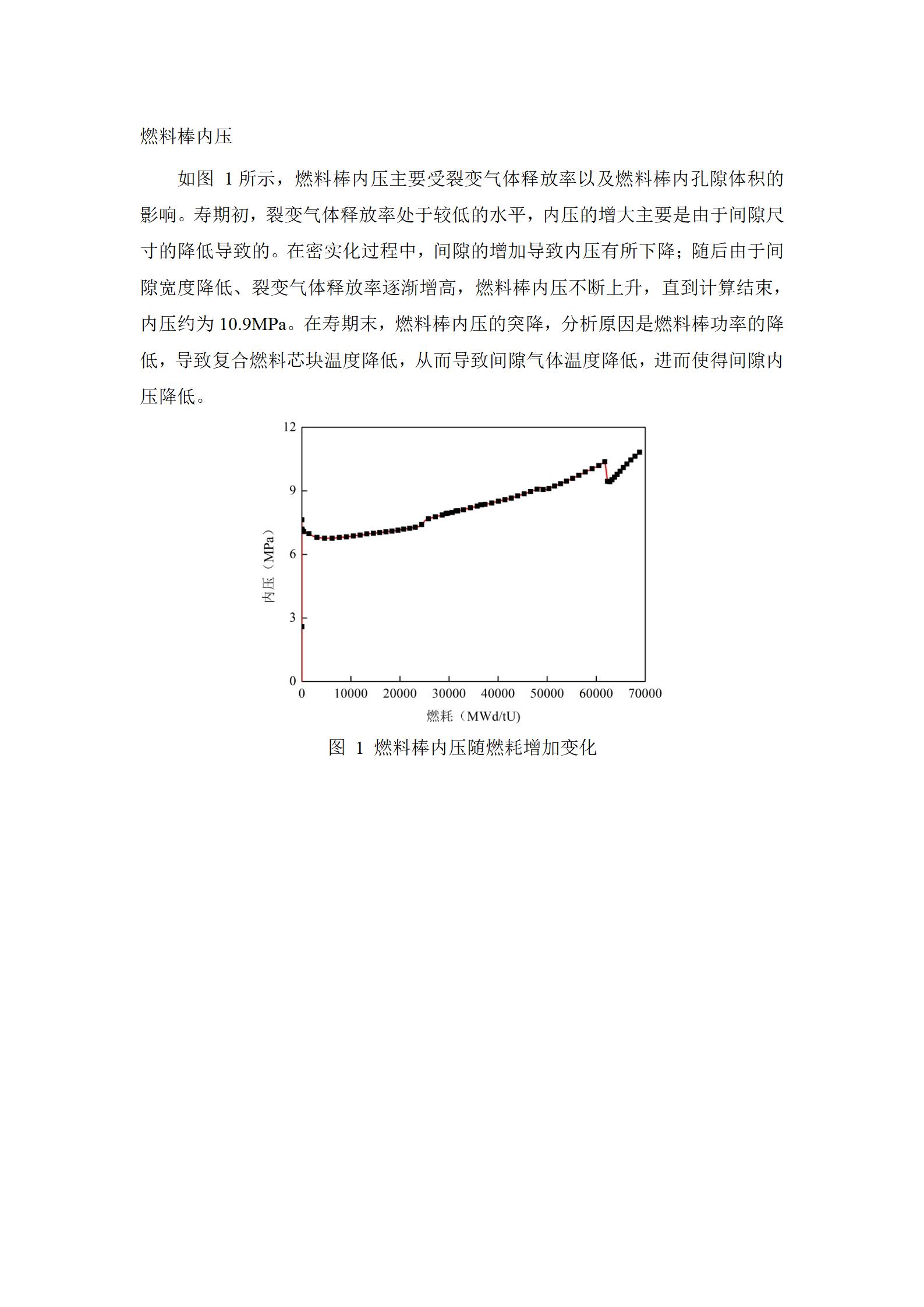

如图 1所示,燃料棒内压主要受裂变气体释放率以及燃料棒内孔隙体积的影响。寿期初,裂变气体释放率处于较低的水平,内压的增大主要是由于间隙尺寸的降低导致的。在密实化过程中,间隙的增加导致内压有所下降;随后由于间隙宽度降低、裂变气体释放率逐渐增高,燃料棒内压不断上升,直到计算结束,内压约为10.9MPa。在寿期末,燃料棒内压的突降,分析原因是燃料棒功率的降低,导致复合燃料芯块温度降低,从而导致间隙气体温度降低,进而使得间隙内压降低。

As shown in Figure 1, the internal pressure of the fuel rod is mainly affected by the release rate of fission gas and the pore volume in the fuel rod. At the beginning of life, the release rate of fission gas is at a low level, and the increase of internal pressure is mainly due to the reduction of gap size. In the process of densification, the increase of gap leads to the decrease of internal pressure; Subsequently, due to the decrease of gap width and the gradual increase of fission gas release rate, the internal pressure of the fuel rod keeps rising until the end of the calculation, and the internal pressure is about 10.9MPa. At the end of the service life, the internal pressure of fuel rod drops suddenly. The reason is analyzed that the reduction of fuel rod power causes the temperature of composite fuel pellet to decrease, which leads to the decrease of gap gas temperature, thus reducing the gap internal pressure.