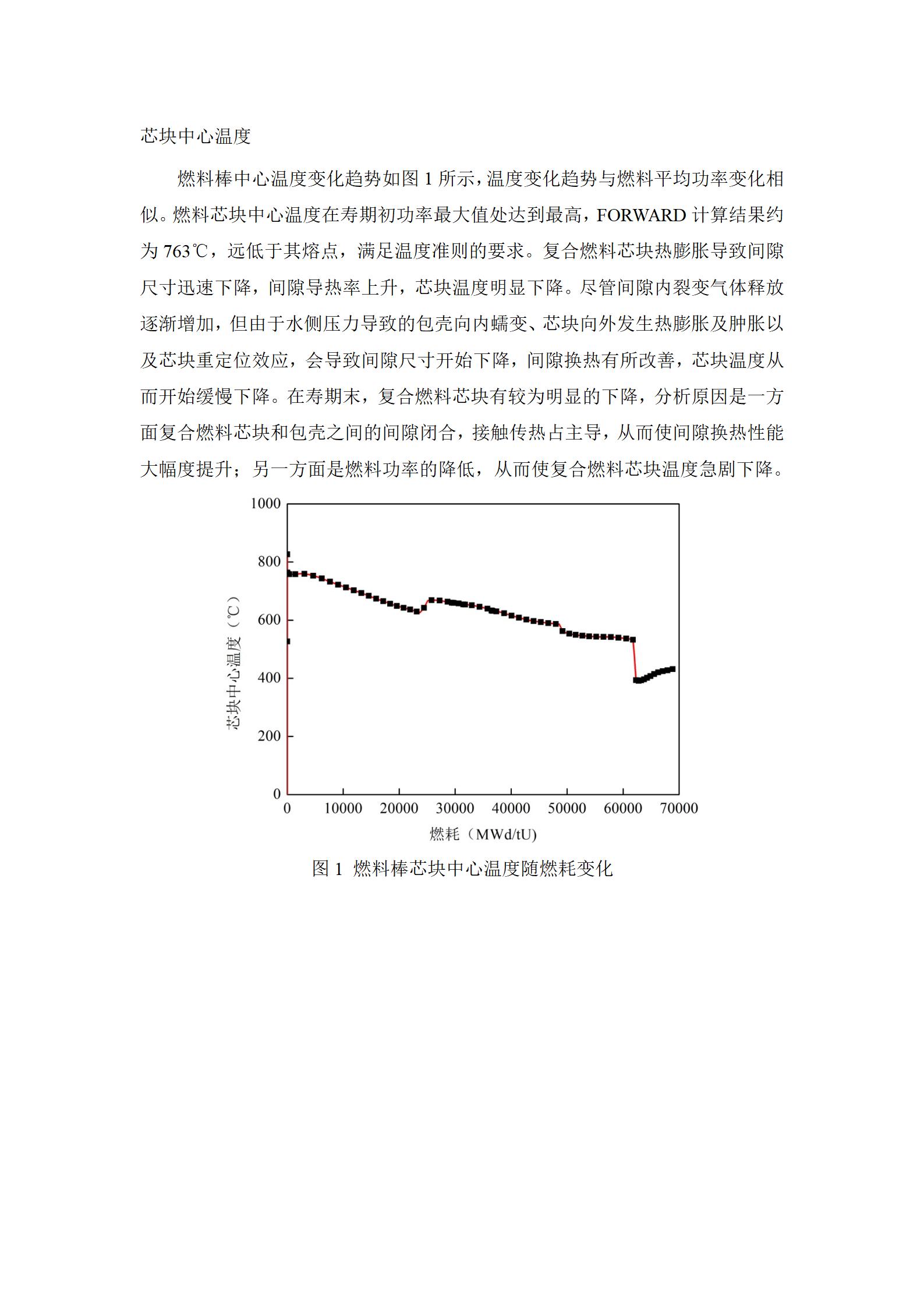

燃料棒中心温度变化趋势如图1所示,温度变化趋势与燃料平均功率变化相似。燃料芯块中心温度在寿期初功率最大值处达到最高,FORWARD计算结果约为763℃,远低于其熔点,满足温度准则的要求。复合燃料芯块热膨胀导致间隙尺寸迅速下降,间隙导热率上升,芯块温度明显下降。尽管间隙内裂变气体释放逐渐增加,但由于水侧压力导致的包壳向内蠕变、芯块向外发生热膨胀及肿胀以及芯块重定位效应,会导致间隙尺寸开始下降,间隙换热有所改善,芯块温度从而开始缓慢下降。在寿期末,复合燃料芯块有较为明显的下降,分析原因是一方面复合燃料芯块和包壳之间的间隙闭合,接触传热占主导,从而使间隙换热性能大幅度提升;另一方面是燃料功率的降低,从而使复合燃料芯块温度急剧下降。

The change trend of fuel rod center temperature is shown in Figure 1, and the change trend of temperature is similar to that of fuel average power. The center temperature of fuel pellet reaches the highest at the maximum power at the beginning of its life. The FORWARD calculation result is about 763 ℃, far below its melting point, meeting the requirements of the temperature criterion. The thermal expansion of the composite fuel pellet leads to the rapid decrease of the gap size, the increase of the gap thermal conductivity and the obvious decrease of the pellet temperature. Although the release of fission gas in the gap gradually increases, due to the inner creep of the cladding caused by the water side pressure, the outward thermal expansion and swelling of the pellets, and the repositioning effect of the pellets, the gap size will begin to decline, the gap heat transfer will be improved, and the pellet temperature will begin to slowly decline. At the end of the service life, the composite fuel pellet has a relatively obvious decline. The reason is analyzed as follows: on the one hand, the gap between the composite fuel pellet and the cladding is closed, and the contact heat transfer is dominant, which greatly improves the gap heat transfer performance; On the other hand, the temperature of composite fuel pellet drops sharply due to the reduction of fuel power.