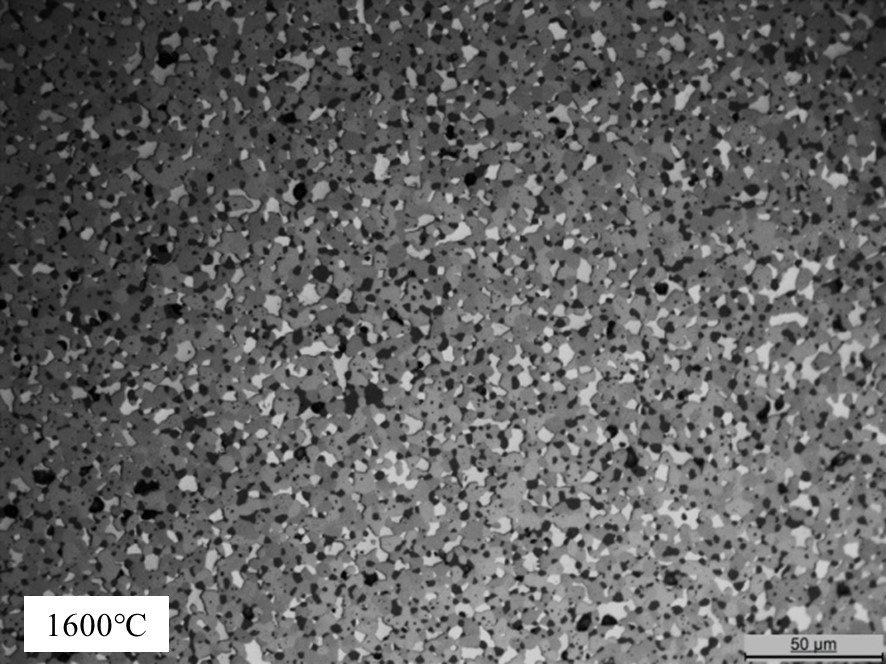

分别在1600℃、1650℃、1700℃以及1725℃下对UN/U3Si2(30wt%)复合芯块烧结2h,然后利用金相显微镜观察UN/U3Si2(30wt%)复合芯块宏观形貌。结果表明,当烧结温度低于1700℃,随着烧结温度的逐渐增加,芯块内部晶粒尺寸逐渐增加;当烧结温度从1700℃增加至1725℃时,芯块内部的晶粒尺寸显著增加。

The UN/U3Si2(30wt%) composite pellets were first fabricated at 1600°C, 1650°C, 1700°C and 1725°C for 2h, and then the macroscopic morphology of UN/U3Si2(30wt%) composite pellets was observed by metallographic microscopy. The results show that when the sintering temperature is lower than 1700°C, the grain size of these pellets gradually increases with the increase of the sintering temperature. Furthermore, when the sintering temperature increases from 1700°C to 1725°C, the grain size increases significantly.