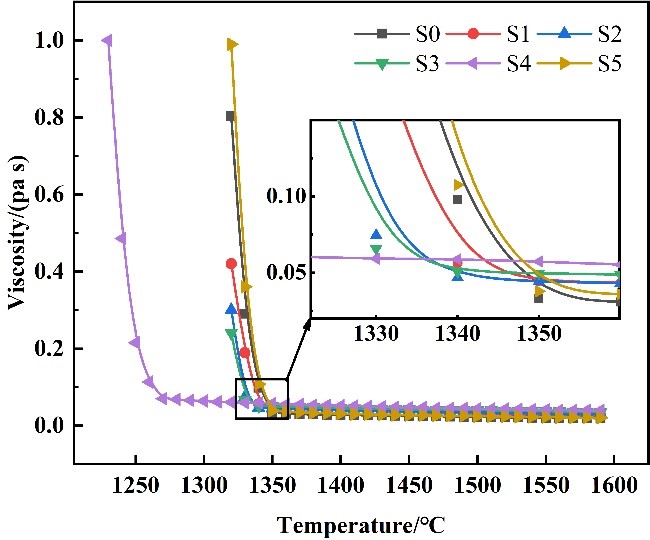

添加不同SiO2、CaO和TiO2的熔渣粘度如上图所示。从S0到S3曲线可以看出,随着SiO2质量分数的增加,熔渣粘度增加。此外,随着CaO含量的增加,炉渣粘度增大,粘度突变点温度明显降低。S1和S5图线的比较表明,TiO2对粘度变化的影响很小。当温度高于1633k时,每种炉渣的粘度基本保持不变。比较发现,熔渣样品S1、S2和S3更适合于GH984G高温合金的熔炼。

The viscosity of slag with different addition of SiO2, Cao and TiO2 is shown in the figure above. From the S0 to S3 curve, it can be seen that the viscosity of slag increases with the increase of SiO2 mass fraction. In addition, with the increase of CaO content, the viscosity of slag increases and the temperature of viscosity mutation point decreases obviously. The comparison of S1 and S5 plots shows that TiO2 has little effect on viscosity change. When the temperature is higher than 1633k, the viscosity of each slag remains unchanged. It is found that the slag samples S1, S2 and S3 are more suitable for the melting of GH984G superalloy.