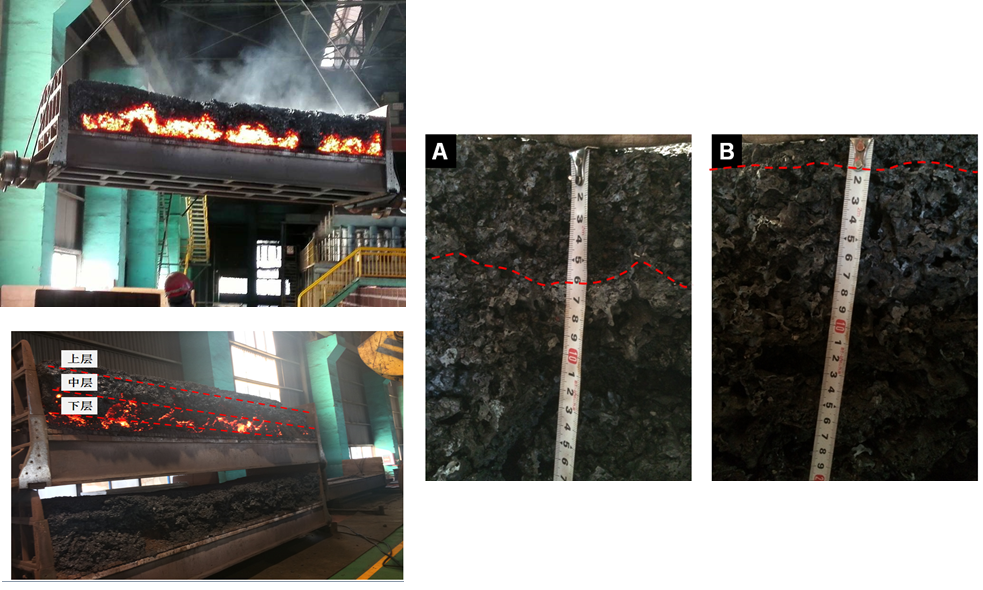

为了验证首钢烧结高温烟气循环工艺对改善烧结矿质量的效果,对热风烧结前后台车表层烧结矿质量进行了对比分析。检测方法是当烧结台车到烧结终点时,将台车取出进行烧结矿的分区检测。从烧结料层断面照片比较可以看出,采用首钢烧结高温烟气循环工艺后烧结表层欠烧矿厚度由常规烧结的50-60mm大幅度降低至20mm左右。说明首钢烧结高温烟气循环工艺可改善表层烧结矿的粘结情况和质量。

In order to verify the effect of shougang sintering high temperature flue gas circulation process on improving sinter quality, the surface sinter quality of trolley before and after hot air sintering was compared and analyzed. The detection method is that when the sintering trolley reaches the sintering end point, the trolley is taken out for the zone detection of sinter. It can be seen from the comparison of cross section photos of sintering material layer that the underfiring thickness of sintering surface layer is greatly reduced from 50-60mm to about 20mm after adopting shougang sintering high-temperature flue gas circulation process. It shows that shougang sintering high-temperature flue gas circulation process can improve the bond and quality of surface sinter.