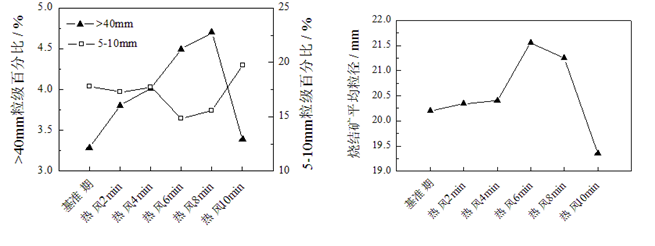

基准期5-10mm烧结矿粒级占17.77%,废气循环烧结时5-10mm粒级五组平均为17.03%比基准期下降了0.74%。相比基准期,废气循环烧结时5-10mm小粒级先下降后又上升的变化趋势。当热风保温时间为6min时,5-10mm烧结矿粒级最低为14.84%,与基准期相比降低2.93%;当热风10min时,5-10mm烧结矿粒级最高为19.75%。基准期转鼓指数为65.73%,热风保温时间分别为2min、4min、6min和8min、10min是转鼓指数分为65.47%、65.73%、66.00%和66.80%、65.0%,热风保温时间平均每延长2min,转鼓指数提高0.27%。呈现先增加后又降低的变化趋势,当废气循环烧结8min时,转鼓指数最高达到66.80%。

The average size of 5-10mm sinter in the base period is 17.77%, and the average size of 5-10mm sinter in the exhaust gas cycle is 17.03%, which is 0.74% lower than that in the base period. Compared with the reference period, the 5-10mm small particle size decreased first and then increased during the waste gas cycle sintering. When the hot air holding time is 6min, the minimum size of 5-10mm sinter is 14.84%, which is reduced by 2.93% compared with the reference period. When hot air lasts for 10min, the maximum sinter size of 5-10mm is 19.75%. In the baseline period, the drum index was 65.73%, and the hot air holding time was 2min, 4min, 6min and 8min, respectively. The drum index was 65.47%, 65.73%, 66.00% and 66.80%, 65.0%, respectively. The drum index increased by 0.27% when the hot air holding time was extended by 2min on average. It showed a trend of increasing first and then decreasing. When the waste gas was circulated for 8min, the drum index reached 66.80%.