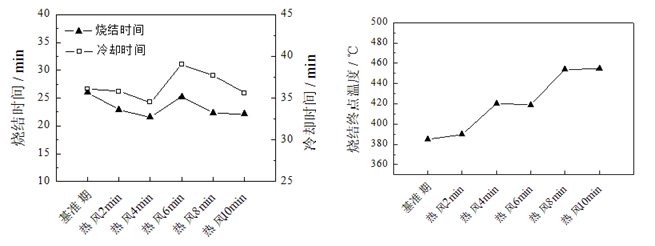

基准期烧结时间为25.97min,废气循环烧结后,烧结时间平均为22.84min,与基准期相比,烧结时间缩短3.13min,呈现明显缩短的趋势;基准期冷却时间为36.11min,废气循环烧结后,冷却时间平均为36.53min,稍有延长。采用废气循环烧结时,烧结时间缩短的原因认为主要是上升点提前所致。基准期烧结终点温度为385℃,废气循环烧结后,烧结终点温度明显升高,平均烧结温度427.6℃,比基准期提高42.6℃。随着热风保温时间的延长,烧结终点温度逐渐提高,平均每延长保温时间2min,烧结终点温度提高14℃。

The sintering time in the base period is 25.97min, and the average sintering time is 22.84min after the exhaust gas circulation. Compared with the base period, the sintering time is shortened by 3.13min, showing a significant trend of shortening. The cooling time of the base period is 36.11min, and the average cooling time is 36.53min after the waste gas circulation sintering, which is slightly extended. The reason for the shortening of sintering time is that the rising point is advanced. The sintering endpoint temperature in the base stage is 385℃. After the exhaust gas circulation sintering, the sintering endpoint temperature increases significantly, and the average sintering temperature is 427.6℃, which is 42.6℃ higher than that in the base stage. With the extension of hot air holding time, the sintering terminal temperature increases gradually, and the average temperature increases by 14℃ for each extension of holding time of 2min.